This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

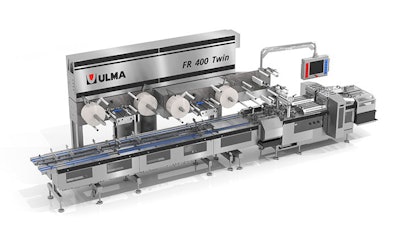

Smart, connected packaging solutions provider Harpak-ULMA announces the North American launch of ULMA’s FR 400 TWIN Flow Wrapper—promising to revolutionize high-volume automated packaging operations with its exceptional throughput and compact footprint.

The unique space-saving design of the high-output horizontal wrapper makes it ideal for facilities with limited floor space or those seeking to expand packaging throughput in existing production environments. The FR 400 TWIN delivers two fully functional FR 400 horizontal flow-wrap machines within the footprint of a single legacy line, effectively doubling throughput within the existing physical constraints of a single, stand-alone flow-wrap installation. Moreover, it delivers up to 700 PPM, or 70 meters per minute of film speed per lane, depending on product size/characteristics, for up to 1400 ppm.

While utilizing a shared frame and HMI for centralized control, the machines are designed for full independent operation—enabling the lines to continue running separately—regardless of the operational status of the other. The user-friendly interface of the FR 400 TWIN simplifies setup, operation, and maintenance so operators can quickly switch between different product configurations. The FR 400 TWIN, built with high-quality materials and components, is engineered to withstand the rigors of continuous production and ensure a long service life and minimal downtime.

“The FR 400 TWIN demonstrates ULMA’s dedication to innovation and a commitment to advancing efficient, effective, highly performant packaging solutions,” said Josh Becker, Bakery Segment Manager at Harpak-ULMA.

“For high-capacity snack, bar, cookie, bakery, or confectionary operations seeking to efficiently scale production throughput sans physical plant expansions, the innovative, compact, high-performance FR 400 TWIN horizontal wrapper should be very attractive.”

Becker explained that efficiency is a keynote of the FR 400 TWIN—enabling producers to scale effectively without a one-to-one operator relationship. “Mirroring the FR 400 TWIN delivers four machines but requires only one operator. The labor savings is obvious—as well as the realization of redundant line capabilities.”