This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

New design for increased safety and efficiency

Thanks to the new ergonomic design with a lowered carton magazine, manufacturers benefit from an easier and safer operation of the machine. In addition, the process of refilling the glue was optimized with an external hot glue tube which protects operators from burns. Both features contribute to increased workplace safety and fulfill increasingly stringent regulations worldwide. Bernhard Vaihinger, head of product management, innovation and technology at Bosch Packaging Systems GmbH, a Bosch Packaging Technology company, highlighted, “Manufacturers have to consider increasingly stringent legal requirements that are affecting packaging machinery design in terms of ergonomics and hygiene. At the same time, they cannot sacrifice productivity. Our new development enables manufacturers to achieve both.”

Format changeover with feedback

Similar to the Elematic series of secondary packaging machines from Bosch, the new Elematic 3001 can handle many different pack styles, including tray, classic full wrap-around and two-part, shelf-ready packaging. This is especially important for manufacturers supporting different brands and products with a variety of pack styles. With the new Elematic 3001, easy and tool-less packaging format changeovers are realized thanks to the so-called “Elematic click system”. When parts lock into place a sound indicates acoustically and a red distance piece optically the successful format changeover. Manufacturers benefit from higher efficiency as time consuming corrections are eliminated and errors while using scales are avoided.

Hygienic design enhances cleanability

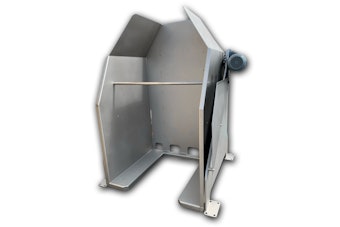

Compared to previous models, Bosch further enhanced the machine’s hygienic design. With fewer components, the frame has an open design and is easily accessible. Horizontal surfaces and corners have been eliminated and corrosion-resistant materials, such as stainless steel, anodized aluminum or brass, are used. In addition, all wiring and cables are hidden due to design-integrated conduits to protect them from dirt and damage. All features contribute to enhanced cleanability of the machine, which increases production hygiene.

Minimized maintenance reduces TCO

The minimized number of components and added new technologies, including servo drives, decrease maintenance work and reduce the Total Cost of Ownership (TCO) of the new Elematic 3001. The incorporation of the total productive maintenance (TPM) concept indicates when maintenance is due, helping eliminate unplanned downtime, and increasing productivity.

To further reduce the footprint of the machine, the company integrated the control cabinet on board, which speeds up installation time at the customer’s plant. In addition, thanks to the compact design of the machine, it meets the sea and air freight standards, decreasing overseas transportation costs.