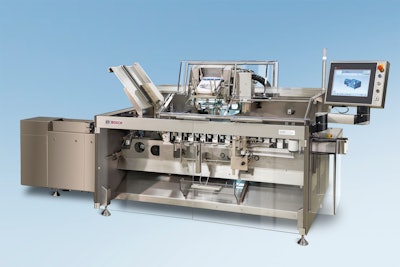

The CUT 1405, an advancement over the CUT 120, provides flexibility including appropriate in-feed systems, formats, and closure options. It can safely and gently handle different carton sizes and packages, a wide variety of primary packaging in folding cartons. Inserts to single and combination products such as spoons or outserts can also be integrated into the modular in-feed system. Exchangeable modules allow tuck-in, glue, and combination closure.

The intermittent cartoner can be equipped with diverse in-feed systems, ensuring maximum flexibility for customized line concepts as well as the packaging of different products and product combinations. The CUT 1405 further features an optimized conveyor technology of the folding carton magazine. To prevent the cartons from getting caught, they are transported into the magazine by a lifting motion of the rake. Thanks to the patented folding carton carrier, the individual cartons maintain their shape as the intermittent transport system moves them through the machine. This prevents damage to the product and ensures precise packaging results.

A mechanical gripper arm carries out leaflet in-feed, which is directly assigned to each product. A shift register checks and follows all products, to ensure that leaflets are only processed further if the outcome of all test results is positive. The folder unit can be conveniently operated from the front and, if required, also swiveled out.

With fewer hardware components in the control cabin, the new servo technology reduces the need for maintenance while the HMI allows easy handling. The operator can quickly localize machine disorders via error messages and resolve them using the automatic troubleshooting guide. All format data is individually stored, enabling easy and quick format changeovers and a safe re-start of the machine.

Optional serialization, aggregation. and tamper-evident modules ensure additional safety, taking into account current guidelines and safety standards.