Schwenk Putztechnik GmbH & Co. KG, of Ulm, Germany, is one of the leading manufacturers of sustainable and ecological dry mortar. The company has produced its materials for more than 160 years in seven ultra-modern plants. "We place great importance on presenting our products optimally in the building material trade," says Martin Markus, who manages the company’s plants in Eigeltingen and Allmendingen in Baden-Württemberg, Germany. As regards the manufacturing process, the company focuses on trouble-free transport, the palletizing process, and packaging.

In the past, Schwenk Putztechnik was not able to ensure a proper and constant appearance of its palletized product. "Our previous palletizing solution caused considerable problems during the turning of bags," recalls Peter Richter, Deputy Factory Manager in Allmendingen. "Due to jerky movements, the bags were deformed and sometimes even torn.” Therefore, the company was looking for a palletizing solution that could not only achieve an improved and steady stacking result, but also increase the production capacity, reduce the dust emissions, and prolong the maintenance intervals.

During their research for a suitable supplier, the company found BEUMER Group. The single-source provider supplies sustainable systems for filling, palletizing, and packaging technology from one source. "In cooperation with Schwenk Putztechnik, we developed a solution that covers the requirements of both production plants," BEUMER Sales Manager Peter Schmidt reports.

Gentle palletizing is ensured

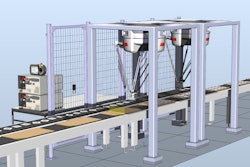

For Schwenk Putztechnik, BEUMER recommended the paletpac high-capacity layer palletizer, which enables the stacking of bags filled with bulk material on pallets layer by layer. Due to the geometric precision during layer and stack formation, stable bag stacks are formed. BEUMER supplied a system able to palletize 1,800 bags/hr as well as a system with a capacity of 2,500/hr. In both plants, the employees can adapt the palletizer quickly and easily to different bag sizes without the use of tools.

With a pack height of up to 2,400 mm, the paletpac stacks bags on any commonly used pallet size and in all technically possible packing patterns. A multi-program interface enables the user to set parameters easily and quickly. The new BEUMER Group Human Machine Interface (HMI) ensures a user-friendly operation of the system. This control terminal provides the employee with an easily understandable and intuitive interaction, enabling the user to learn the system very rapidly and to define efficient working sequences after just a short training and introduction period.

Stable stack formation

In order to turn the bags rapidly and gently to the required position to ensure their dimensional stability, the paletpac systems are provided with BEUMER’s newly developed twin-belt turning device. “In regards to the stackability, this device offers an immense advantage when compared with conventional turning processes,” Schmidt explains. The system component moves the bags without stressing them from a mechanical viewpoint. Instead, two parallel-driven belt conveyors are used, which during the turning process are driven with different speeds, bringing the bags gently into the desired position. The intelligent control of the twin-belt turning device involves the physical properties of the items to be packed in order to achieve an exact positioning preset by the respective packing pattern.

In case of changes in bag sizes, all relevant parameters are registered and controlled via software. For this, the system reverts to an active control loop. The regulation of the drives is carried out by frequency converters, thus developing a gentle, regular rotation and ensuring that the bagged products are not deformed. This results in constant stack results for the whole service life of the system. Ready-packed pallets can be stacked on top of each other in space-saving and safe way.

A further advantage is that time-consuming modifications of changed bag sizes are no longer required. "The operator only has to enter the bag length and the bag width. Then the system brings the bag into the corresponding position,” explains Bernhard Temming, Service Manager at BEUMER.

Because of the modular structure, the twin-belt turning device can be retrofitted in existing palletizing systems in quick and trouble-free way.

Quiet and efficient

A further reason Schwenk Putztechnik opted for the BEUMER systems was their efficient operation. In addition to capital costs, operational costs, spare parts costs, and maintenance costs also play an important role. "These are better reduced with the twin-belt turning device than with other turning devices," says Temming. "The automated product change avoids idle times," and as the system component abstains from cost-intensive mechanical components, this optimizes the maintenance and repair costs in the long term and reduces the life-cycle costs. "Comparable solutions of competitors for the layer preparation rely on pneumatic elements with correspondingly high operational costs. In our twin-belt turning devices, work is done by energy-efficient synchronous servomotors,” adds Temming.

The relinquishment of mechanical parts additionally lowers noises during operation.