This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

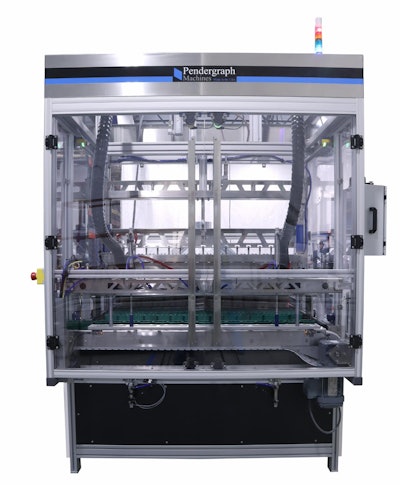

ProSys Fill, LLC, a distributor in the design and manufacturing of automated filling equipment, highlights the Flex Fill 120, a fully automatic hot melt filling system designed for high-speed, high-precision filling of deodorant sticks and other large format hot fills starting at .5 oz. Designed and manufactured by ProSys’ exclusive partner Pendergraph Machines, the Flex Fill 120 delivers up to 120 parts per minute and supports a range of container shapes and sizes.

The Flex Fill 120 features servo-driven filling for accuracy and repeatability, with positive close nozzles and suck-back to prevent dripping. Integrated cooling tunnels ensure rapid and uniform solidification of products, preserving quality and appearance, and an optional remelt station is available for smooth top fills.

The system automates the entire process, including puck loading, stick sorting, filling, cooling, plug and cap placement, and de-pucking, minimizing manual labor, and maximizing throughput. Features such as in-line labeling and a reject station are available to support traceability and quality assurance requirements. Operators benefit from a user-friendly touchscreen interface that simplifies recipe management and changeovers, making it easy to switch between product formats with minimal downtime.

The Flex Fill 120 adapts to various packaging requirements and supports high-volume production without sacrificing accuracy or quality. By combining precision engineering, advanced automation, and versatile configuration options, the Flex Fill 120 sets a benchmark for hot melt filling solutions. ProSys Fill’s commitment to innovation and customer-focused design empowers manufacturers to meet the demands of dynamic markets and deliver superior products with confidence.