Blake Hutzley knows too well what it takes to come-up with innovation in a tough product category. Prior to his current role as technical advisor at the Biscuit & Cracker Manufacturers' Association (B&CMA), he spent most of the last four decades at Kellogg Co., as well as other leading brands including Keebler, Frito-Lay, Lance, Continental Baking and others.

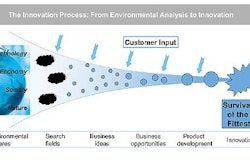

“The innovation process can apply to almost any industry,” Hutzley said in a Pack Expo 2014 presentation. There are many innovation processes, he said, naming some — Stage Gate, Creative Problem Solving, Product Development and Performance Measurement Data System — but they generally follow a common path of steps of ideation, validation, prototypes, testing and more.

“But someplace along the way, in my experience, we’ve lost something,” he said, because instead of “little stop sign” type decision points between development stages where team leaders offer go/no-go advice, the number of people on development teams often grows exponentially, bogging down the process so that instead of moving forward, projects “get stuck in the mud.” He explained this problem by way of a story from his Big Brand past.

A tale of all-too-common inefficiency

“I got together with two or three people, and we had an idea for a new cookie,” they agreed, and ordered the R&D lab to come-up with three prototypes. “We took the three prototypes into the next meeting, but this time instead of just three people, I’ve got 20 people” including people from sales, production, engineering, finance and others.

“By the time this meeting was over three hours later, I had to go back and make five variations of [each of] the three prototypes.” The meetings continued, he told the audience, until “three months later, when the deadline came and we needed a new product, we just grabbed something off the shelf and said, ‘Make it.’ The whole process was a waste of time.”

Let the three Cs guide you

The secret to a successful product innovation process, then, isn’t more complexity, or the nuts and bolts of the complex processes R&D departments have spent years honing. It’s about focusing on three little Cs: capacity, capability and capital.

- Capacity: Being able to produce enough product is critical to a product innovation’s ability to reach the widest matter possible. This gotten through idle in-house assets or contract manufacturing or packaging partners.

- Capability: “I can do anything if we have the equipment with the capability to do it,” Hutzley said, stressing the need to understand the scope and timeline of what’s needed “right now” vs. what can be planned and budgeted.

- Capital: Speaking of budgeting, any innovation “can be had with the third C.” How much money is available is critical to the extent of innovation, Hutzley said.

He also stressed that while the Three Cs are conceptually simple, it’s critical to have the right people in place who can accurately evaluate, measure, plan and deal with those three Cs to with the right depth and focus. For those in his sector, the B&CMA offers extensive educational programs; those in other sectors may find the training they need from other trade associations and professional organizations.

“The Three Cs can be applied to any type of innovation,” he said, adding that companies can get a very accurate read on whether a new idea will fly if “you get the right people together to evaluate these three Cs.”