Are environment-related packaging changes taking a back seat this year? That was the crux of questions Packaging World posed to selected readers, some in management, some in production and engineering. Via telemarketing, PW sought to find out whether there was any measurable difference in the way corporate and plant people viewed the effects of the environment on packaging.

For the most part, the results show that both management and engineers tell pretty much the same story: yes, the environment is still an issue in packaging, but many of the major changes have already taken place.

In this survey, PW worked with Leading Questions, Inc. (Appleton, WI), a research company that specializes in telephone interviews. In this study, Leading Questions contacted 50 to 60 PW readers, each holding management positions or engineering/production responsibilities in manufacturing companies across the country.

Unlike the pricing survey (see p. 00), there are no claims that these results would be projectable over all Packaging World readers. Given the size of the samples, there is no way to predict the validity of the responses. Nevertheless, there are both interesting similarities and some notable differences in the way management and engineering/production personnel view the importance of the environment to packaging in 1995.

To set the stage, PW asked whether environmental concerns have influenced packaging at their companies. Nearly four of five in each group answered yes: 78.6% of management people and 76.9% of line employees. The bigger surprise is that over 20% of each group answered no!

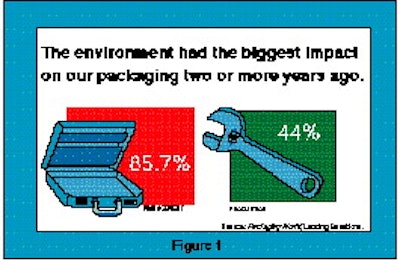

Then, these readers were queried about what time period had experienced the biggest environmental packaging changes. More than any other question in this survey, the answers to this question suggested a sizable gap between management and line personnel. (Figure 1).

Two-thirds of management respondents said the environment had the greatest effect on packaging three or more years ago. That built to 85.7% of management participants who said it was two or more years ago. On the production side, just 28% responded that the impact was greatest three or more years ago. And that increased to just 44% who said two or more years ago. For graphic purposes, we're using a briefcase to represent management responses, a wrench to depict the answers of engineers and production people.

So management readers were about twice as likely as production and engineering readers to say the biggest changes had occurred two or more years ago. Some 12% of the plant personnel said the greatest impact would be this year or next.

In planning the survey, PW editors wanted to measure if there was a gap between policy-making at the management level and the execution of those policies on the packaging line. The answers noted above suggest that corporate executives and plant and line personnel that put changes into production may not always agree.

To the credit of the companies we queried, this timetable was virtually the only question where there was a major difference in the responses. As you'll see in the results of other questions, usually both management and production/engineering respond in a very similar manner.

Changes still in works

While many say the biggest changes had occurred in the past, a high percentage of both groups say more changes are in the works. Some 72.7% of management and 70.8% of our plant personnel say more environmental changes are still being considered.

For those still considering more changes, PW asked when those changes will be put in place. From our sample, over half of both management and engineering people don't really know when the changes will be in place. (Figure 2). Slightly more than 35% of management respondents say the changes will be in place this year or next, but just 25% of the plant people use that timetable. Of the plant operating people, over 68% said they don't really know when the changes will be implemented.

Is this the natural difference between those who plan for packaging changes and those who execute the plans? Perhaps it is. Or maybe it's the more practical difference between those who establish long-term goals and those who work day to day to make those goals a reality.

Later in the survey, readers were asked whether environmental concerns will be a part of each company's packaging plans for '95 and 1996. Like many other questions, the responses were similar. Some 78.9% of management said yes, compared to 83.3% of the plant people.

Strategies are close

When respondents were asked about the changes that were caused by environmental packaging concerns, the responses from both groups were similar. The management participants voted most for looking at different materials (26.2%) and working with vendors to source reduce packaging (21.3%). Each of those responses were mentioned by 24% or more of the production/engineering respondents.

Along with U.S. environmental packaging concerns, PW queried the respondents about the importance of Canadian and overseas packaging restrictions. (Figure 3). Some 42.9% of the plant personnel said these laws were not important, while another 32.1% said they were very important. On the management side, 31.8% said they were unimportant while 27.3% claimed they were very important. More than anything else, this divergence suggests primary differences between the companies contacted. As pointed out in a sidebar (see p. 00), they range from major national brewers to rather modest local end-users.

In a similar vein, the readers were asked about their knowledge of "rates and dates" laws in the U.S., where states require certain recycling levels or recycled-content percentages for certain packaging materials. Although PW has published articles dealing with the several states that have passed these rates and dates laws, the majority of both management and production people contacted in this survey said they were unfamiliar with those laws. Surprisingly, 70.8% of management readers said they were not familiar with the laws, compared to 61.5% of the line personnel who said they were not well-versed in them.

How to meet requirements

Obviously, relatively few of the participants were prepared to address the issue of their company's responses to "rates & dates" state laws. Of a handful of choices, the management participants looked to "develop packages with recycled content," "seek exemptions from the law" and "to consider withdrawing their products from these states."

Since more of the line people answered the question, their answers were more diverse. Some 31.4% of line personnel agreed with management that their companies would seek packages with recycled content. Unlike management, another third said their company's primary response would be source reduction. And 12.5% of production/engineering people expected that recycling levels would be sufficient. Fewer participants expected their companies to fight the legislation, to seek exemptions or to consider withdrawing products from the states with "rates and dates" laws.

For respondents who reported that their companies had made packaging changes because of the environment, the survey also inquired whether the company called attention to the changes through copy on the package or in advertising and promotion. Of the management participants, some 56.2% said there was no attempt to call attention to the change. From the production/engineering group, 60.9% said the same.

Help from Congress?

The survey also queried participants on whether they anticipated that the new Congress and the state legislatures may provide some relief from environmental laws. Neither the managers nor the engineers really expected help.

Over half of each group said they didn't expect that Congress or state legislatures would have any effect on environmental packaging requirements. In fact, if we combine those who said Congress and the legislatures would have "little effect" to those who answered "no effect" on their companies, they totaled 82.6% of the line personnel and 69.6% of management participants.

Of the management participants, some 17.4% admitted that they didn't know what effect Congress and the legislatures might have on environmental laws affecting their company. Another 13% felt that the actions of newly elected officials could delay or suspend the implementation of some packaging changes.

None of the engineering/production participants ventured opinions as broadly as management. Aside from those who felt the officials would have little or no effect, all of the balance were unsure if the newly elected federal and state legislators would have any effect on their company's plans to make environment-driven changes to packaging.

Pricing a modest factor

Because we obviously touched a nerve or two among purchasing people when they were quizzed about material prices (see PW August '95, p. 62; p. 00 of this issue), PW inquired whether material prices had much of an effect on environmental changes in packaging.

The managerial participants, not surprisingly, could better relate that pricing had caused some ripples in how their companies dealt with environmental changes. Over 46% of these responses said that increased costs had forced reviews of other material options. Still, another 30.8% said pricing had no effect on changes. But nearly 25% of managers said the cost increases had slowed changes or, in some cases, even stalled environmental packaging changes.

The numbers were markedly different from the production/engineering participants. Of these, fully 50% said package pricing had no effect on package changes. Some 28.6% said that costs had increased the need to look at alternative materials, and the remainder, 21.4%, said that material costs had slowed down implementation of package changes that respond to environmental concerns.

Packaging material costs is not only a sensitive issue, but these results show it's a predominately management concern. Had the survey asked about packaging machinery costs, it's likely the answers would have been more uniform. Many plant personnel are most concerned with delivery and performance of materials, while managers juggle the numbers. So the survey also asked about performance of materials and machines.

Modest effect on operations

Finally, the survey asked both groups whether packaging changes that respond to environmental concerns had much effect on company operations. Here, the responses show a marked dichotomy. (Figure 4).

Among managers, for example, 54.8% said the changes had no effect on company operations, and another 16.7% said the effect was modest. However, more than one in five said the effect was noticeable, and another 8.3% claimed that the changes had an extreme impact on company operations.

The same ratio came through from the respondents with production/engineering responsibilities. Some 73.7% reported a modest or "no effect," but 26.3% claimed the impact was noticeable or extreme.

Even when the questions were more specific and definitely more related to the experiences of line personnel, the answers were close enough to be considered a wash. (Figure 5). PW asked if the package changes had increased downtime. While the production/engineers split evenly at 50% yes, 50% no, managment responses were reasonably similar at 42.9% yes, 57.1% no.

When asked if the changes affected machine performance, 83.3% of the line people said yes, 62.5% of management said the same. The survey also asked if the changes had an effect on package performance. Some 80% of management reported yes, while about 60% of production/engineers agreed. Among the unsolicited reasons cited for the impact on package performance, several respondents volunteered that packaging with recycled content simply did not perform as well as packages made of virgin materials.

Wide range on importance

Leading Questions concluded the interviews by asking how important the environment will be in packaging for the remainder of this year and next. Much like the 3:1 ratio of those who felt the environment had little effect on company operations, a similar ratio was apparent in those who apportioned the importance of environmental packaging in the near future.

Of the managers, the number who responded "very important" were offset by the same number who answered "not very important." A sizeable number said the environment would be among the top five issues, but an equal number felt the issue was "average" or "top ten" or "somewhat important."

The engineers showed a similar range of answers. Those who responded "very important" were largely offset by those who felt the environment would be only "moderately" or "not very important."

Perhaps the most prescient response was made by an engineer. When asked the importance of the environment to his company's packaging, the engineer replied: "It is our customers' concern, so it's very important to us."