With nearly 250 International Safe Transit Association certified package test facilities across the United States, it’s highly likely there’s one not too far away from where you are.

And it may be as close as your state university if you live in California, Indiana, Michigan, or New York. That’s where ISTA-certified university test sites are located at San Jose State University in San Jose, Indiana State University in Terre Haute, Michigan State in East Lansing, and RIT in Rochester. One company that taps this resource regularly is Grote Industries, which uses ISU’s test labs to confirm the package protection for its lamps (see sidebar, link below).

Your choice: Labs or consumers

“All packages are tested,” says Ed Church, ISTA’s executive director, speaking at a May 10 conference on package testing in Rosemont, IL, during the Contract Packaging Services Expo. “The question is, will the package be tested by you so you see the results, or tested by the real world where your customer will see the results?

Global commerce is about more than damage prevention. It also involves control of packaging and shipping costs, as well as reduction of waste.”

There are many levels of testing, from simple to complex, but any testing is better than none, according to Church. While field tests and basic guidelines for specifying material construction can help, laboratory testing creates a miniature universe where the tester has control and can observe, up close, variables and results. Not only for basic hazards such as shock, compression, and vibration, but atmospheric testing for temperature, moisture, high altitude (low pressure). The latest in lab testing is vibration under vacuum, which reveals leakers some tests never uncovered.

“In most organizations,” says Church, “packaging is looked at as an expense.” But real lab testing can give you a bigger picture. Maybe adding more fill [at additional cost] would allow you to ship by a less expensive distribution system, achieving overall savings.”

Another Church insight: Why overpackage in an attempt to achieve 100% damage-free packaging? Maybe 97% is much more affordable, and the last 3% is not worth the savings compared to product replacement.

ISTA offers 23 different test procedures. To find an ISTA-certified packaging test lab near you, use the following link to access the ISTA locator database.

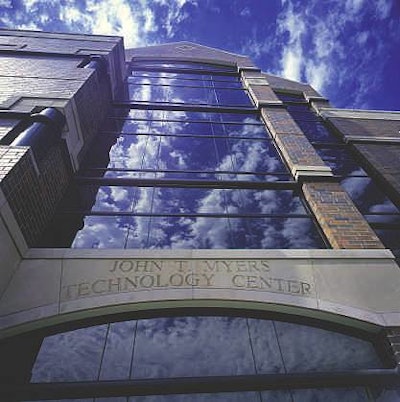

PHOTO: The John T. Myers Technology Center on-campus at ISU houses the Indiana Packaging Research and Technology Center, which is featured in the sidebar to this article. To view the sidebar, please click here.