The glut of products coming onto the market today is increasing competition for consumers’ pocketbooks. In turn, manufacturers, logistics service providers, and retailers are being challenged to improve their marketing and supply chain processes.

These developments are increasing demand for contract-packaging services and pressuring the companies that provide such services to operate more efficiently than ever. Consumer packaged goods (CPG) companies and retailers are demanding that co-packers minimize and control costs and also meet shorter product lead times.

New technologies are coming on the market to help co-packers control costs, monitor production flow, prepare competitive quotes quickly, and perform other essential tasks that help them get to market faster. The software improves CPG companies’ and retailers’ visibility into their projects from a distance and also helps them monitor cost reductions for long-term projects.

There are many software programs on the market that may assist in co-packers’ operations, but following are two new ones that might meet their needs.

• Packaging performance management software, from Nulogy Corp. Toronto, Canada. The company’s commercial production management system is designed specifically for packaging. It can help users reduce product costs, increase customer service levels, and provide support for RFID, calendar-view project scheduling, quote optimization, and Web-based reporting and business intelligence.

• Three-dimensional packaging design and workflow management software, from EskoArtwork, Vandalia, OH. Contract packagers can use the software to digitally design packages. Graphics designers use the same software to lay out images on the digital packages. Working in the same system cuts design time and eliminates the need for several physical package prototypes.

Performance management

Developing quotes and tracking costs can get tricky in the typical made-to-order co-packing environment where line setup and manufacturing quantity changes with each project. Standard manufacturing plants run one item on one production line day after day, simplifying labor staffing decisions on the line and pinpointing areas where efficiency could be improved. A contract packager, how-ever, runs one project one day, another the next. To isolate best operating practices, the best hope is to compare similar jobs over time.

“A variety of things affect your net production at the end of day,” says Chris Nutley, president of MSW Packaging, a contract packager in Lawrenceburg, IN. “The difficulty is in finding where hidden costs lie and how they affect production numbers and then react to them.”

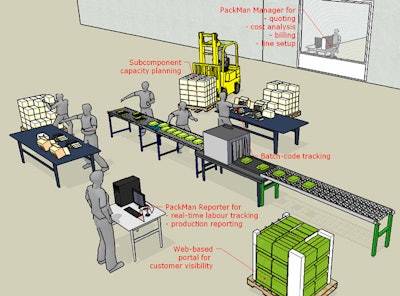

MSW is tackling these and other challenges by turning to Nulogy’s packaging performance management software, called PackManager. The system provides quote-to-ship management, project costing, a Web-based RFP/quoting workflow, capacity planning, bill of materials verification, automated project scheduling, real-time operational bench marks and production status information, and single-click billing for multicustomer relationships.

The system consists of office, floor, and database modules that integrate with a packaging company’s existing information technology, says Kevin Wong, Nulogy vice president of operations.

Nutley says MSW installed PackManager in summer 2007. The system is helping the company track and analyze packaging expenses and also reducing costs by eliminating production-line inefficiencies and building the best line for any given job. Other benefits, Nutley adds, are setting appropriate staffing levels for each project, preparing competitive quotes for CPG companies, tracking and reducing labor costs, and designing prototype production lines for future projects.

MSW is a co-packer for several top food and beverage companies. It packages mainly multipack paperboard cartons, though it also prepares shrink bundles and can run shrink-sleeve label applications. Five production lines operate during two shifts, with a full-time production staff of 42 and a management team of 10 people.

Controlling material costs

“Because contract packagers are becoming responsible for purchasing and supplying packaging components, you have to have control over material costs,” Nutley says. “Ten years ago, shrink film was shrink film was shrink film. Now, we use six different types on the floor, with a wide allocation of costs for each one.

“The costs can get away from you long before you feel the effect. This software system allows us to keep up on supply cost and keep pace with line efficiencies when we purchase material.”

The performance management software tracks projects as they move through the MSW plant. The system captures information like volumes produced, time spent on the line, and labor arrangements. The system gives executives immediate feedback into labor and material costs and compares those numbers with production levels, providing critical information to run lean packaging lines.

During this first phase of implementation, the system helps MSW track labor and line costs and prepare customer quotes. In the near future, Nutley says, MSW will tap the system’s costing capabilities by determining digitally how to best configure its plant for a particular project.

Previously, MSW arrived at cost-cutting measures by analyzing numbers after completing each job. The idea was to use those analyses to drive inefficiencies from future runs and to accurately quote similar jobs in the future. In reality, analysis was easier said than done, Nutley recalls.

“Now, if we put something on the line for an hour, we can track it,” Nutley says, noting that tracking is done using the Internet. “For our old method, if it was on the line less than two hours, you couldn’t follow it.”

Better bidding

MSW now relies on the PackManager software to prepare bids and to compete for jobs. Its time-to-quote has been cut “dramatically,” Nutley says.

The system saves manufacturing data on all past jobs. Managers call upon that information when preparing new quotes. Populating bids with already available information shaves days from the process, and viewing data on past projects allows managers to quote the best price for similar projects.

“Even just a few days’ difference in the quoting process makes us more competitive,” Nutley says. “We can put a quote in the same day or next morning, whereas historically, we’d go back and look at a list of similar projects,” and rely on memory and trust that good notes were taken on old but similar projects, to use as a point of reference. Using the new software, managers refer to stored quotes after a project ends to compare how close the co-packer’s quote has matched actual costs.

Preparing quotes in this way, MSW determines exactly what level of packaging and automation equipment is necessary on each line for each project. Line-staffing levels are determined in the same way.

Expediting package design

Co-packers are moving further upstream of activities like primary and secondary packaging and into services such as package design. Software including 3-D package design and workflow management software, from EskoArtwork is one option for digitally designing packages and working through approvals faster, thereby reducing time to shelf.

Graphic designers use the same software to create images on digital packages. By working in the same system, contract packagers who offer design services can reduce design time in part by eliminating the need for physical package prototypes. Sample designs can be viewed and manipulated on a computer screen, says Mark Vanover, vice president of marketing, EskoArtwork.

The 3D software’s packaging preproduction features include the capability to structurally and graphically design packaging in a digital environment and the capability for both structural and graphic designers to collaborate in the same environment.

The system allows packaging engineers to plug in both package and manufacturing line parameters. Designs are modified on-screen, with others on the creative team providing feedback. The software is also helpful when working with more complex packaging designs, such as those involving full-body shrink-sleeve labels, Vanover says.

Collaborative features of the software enable packaging engineers and graphic designers to work together in real time. When a shrink label is involved, for example, a packaging engineer designs the package structure, then hands off the digital package image to a graphics designer, who creates label images that wrap properly around the packaging and account for the appropriate amount of distortion when the film is shrunk.

That approach eliminates the delay in waiting for physical package prototypes and saves time and money when actual package samples aren’t required.

The author, Jean Thilmany, is based in St. Paul, MN. Contact her at [email protected].