This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

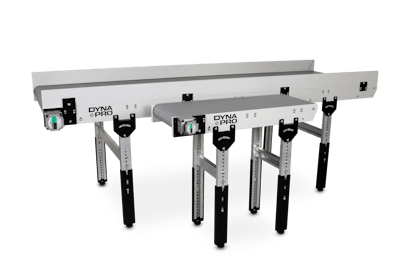

The DynaPro low-profile slider bed conveyor can be used across various industries, including general manufacturing, parts manufacturing, parcel/packaging, injection molding, and medical device manufacturing. The low-profile conveyor has extensive applications, from being used with pick-and-place robots, to completing transfers of all sizes, to being used as a takeaway conveyor.

The conveyor features a tensionless link-style belting to prevent tracking issues and allow for easy belt repair in lieu of replacing entire belts. Further, the DynaPro incorporates many standard features that most other conveyors have as options. These standard features include variable speed, reversing, nose bar design for tight transfers, and an M12 connector for machine integration.

The DynaPro low-profile conveyor helps companies achieve their energy-efficiency and sustainability goals since they utilize compact, high-efficiency 60W and 120W DC brushless motors. Relative to other low-profile conveyors utilizing large 3-phase AC motors, the DynaPro conveyor saves an estimated 30% on energy costs over a year running single shift.

“There was a gap in the market for a quality, low-profile conveyor that offered modular link style belting with a variety of features that were standard rather than add-ons. We are pleased to fill that need with a high-quality product, at an affordable price-point, and with a compressed lead time that will set new industry standards,” says Matt Zehr, manager of engineering, Dynamic Conveyor.