This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

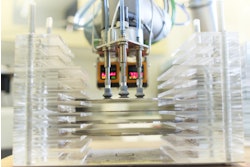

The high speed solenoid valve ensures the most consistent operation and dosing accuracy. Meler’s hot melt dot applicator has a robust design to provide extended cycle life, and features for reduced energy consumption include insulated pneumatic tubes and “Cool-Touch” insulated applicator covers. An integrated filter keeps nozzles clean and is quickly changed without disassembling the hose or applicator. The compact applicator size ensures simple conversion from standard adhesive heads. Packagers will also save on equipment costs, as Meler technology is conservatively priced at 25 to 30% less than comparable dot application systems.

For hot melt seals, the “start” of the bead is where the strength of the seal lies, and once broken, the seal integrity is compromised. Adhesive dots (or dashes) provide superior bonds by creating a new “start” at each dot, with the seal integrity intact until all the dots are broken.