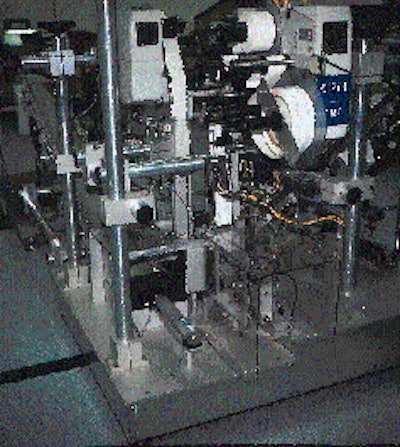

Baxter saves $40ꯠ a year in materials by unitizing two cartons with two labels rather than adding an outer paperboard sleeve. This is accomplished on a one-of-a-kind labeler from CCL Labeling Equipment. The labeler is equipped with an Allen-Bradley laser scanner, CCL thermal-transfer imprinter, and an Allen-Bradley system that provides 100% on-line verification of product identification bar-code labels. After a carton emerges from a compression station, it drops into a staging area where a pusher arm moves it against the back of the area to provide space for the subsequent carton. The two side-by-side cartons are held vertically. The two cartons are gently compressed for label application. Two labels are applied by two labeling heads, one at each end of the compressed cartons. Labels are supplied by Fasson Roll Division (Painesville, OH). The 50# paper release liner/adhesive/facestock label is printed and die-cut by Label Printers (Aurora, IL). Labels are mounted on two unwinds on the CCL labeler and applied in a two-stage process. In a first stage, the printed labels are scanned by an A-B laser scanner mounted to the CCL unit. Next, a CCL ALX-910 thermal-transfer imprinter prints lot and expiration date. The preprinted bar code is then verified by an A-B decoder. "This is essential so that the proper labels are always applied to the proper cartons," says Stevens. "We've always done this, but soon the FDA will require 100-percent on-line verification of all printed label materials." McMillan adds, "By verifying prior to label application, we make sure an inappropriate label will not be applied." Finally, labels index to a second stage, where two vacuumized pneumatic applicators apply labels to carton ends. At both ends of the cartons, a set of rollers flatten the label to both ends and about 4" down the sides of the cartons. The result is a unitized 24-pack that requires no outer sleeve, hence the material savings. Each label contains a small tab. By pulling the tab, the hospital pharmacist can separate the cartons as needed. The label material's proportional tear characteristics allow for a clean, straight tear. With the tear strip removed, both cartons have identical end labels.