This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

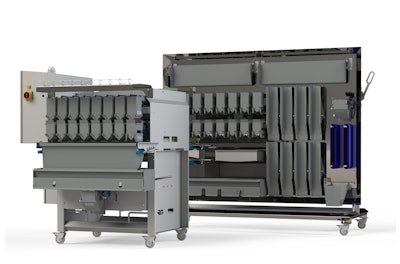

Newtec’s Mini Weigher provides a sustainable solution for working with large product quantities with a minimal giveaway of less than 0.4% and a small footprint, which makes it easier to handle and connect to other Mini Weighers. Its small footprint (as stand-alone or as a line with more machines connected) also makes possible the preservation of space with a much stronger reliance on flexible and automated machinery for the same production rates.

The reality of Brexit made increasingly clear the need for maintaining company production levels while reducing labor costs and reliance. Combined with the increasingly widespread demand for sustainability practices, Newtec’s services as a fruit and vegetables automatized machinery supplier could not be more relevant for customers who are looking for cost-effective and efficient solutions, especially during a time in the UK when manual labor shortages can pose challenges for the production industry.

Newtec UK technical sales manager Paul Graham says: “Over the past three years, the challenge has been getting the labor to pack these products manually, so not only is there a cost-saving by machine packing, but it also means that we can continue supplying our customers.

“Currently, labor is very hard to find with a lot of the immigrant labor returning home after Brexit. Manual labor is not readily available and the skill levels are not consistent and that means that there is the need to constantly train operators.”

Newtec’s Mini Weigher solutions (for example, six Mini Weighers connected across two lines or four Mini weighers connected in one line) are complete automated weighing and packing line that functions at high capacity and are capable of processing, mixing and packing products both with ease and high speed of operation. This means that the customer’s aim to pack mixed products quickly and efficiently while reducing the need for work by hand can be met successfully. This is due to the modular configuration of the Mini Weigher enabling accurate weighing (according to recipe), the mixing of a wide variety of fruits and at the target weight.

The Newtec 2008 PCM machine can run a single unit or it can be networked to run multiple products. Each machine is a combination weigher, giving high accuracy at up to 70 portions/min from 50g to 500g.

On a four-product mix, three products are individually set to a given weight and then the last fourth product can be used to top up to the target weight required.