BluStream is a simpler process which makes sterilization easier to monitor. The process only depends on three critical easy to control parameters: voltage, current intensity and exposure time.

The treatment is compatible with all kinds of plastics; HDPE, PET, PP, PS, whatever the weight or shape of handle. All bottle sizes can also be treated, provided that the neck diameter is above or equal to 30 mm. Treatment efficiency allows this method to be used for high-acid products (fruit juices) as well as for low-acid products (cow milk, soy milk, other vegetable milks and all nutritional products).

Unlike peracetic acid (PAA) and hydrogen peroxide (H₂O₂) treatments that rely on chemical principles, BluStream is based on a physical process. It uses an issuer which throws an electron beam over the container’s surface. Electrons quickly destroy micro-organisms by breaking their DNA chains.

BluStream treatment is also more economical in production because it requires no chemicals, no water, no compressed air, and a minimum increase in electrical consumption comparable to the H₂O₂ treatment.

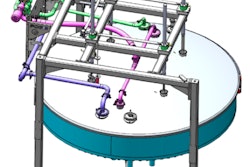

The system is more compact than PAA and H₂O₂; the floor area is only 215 sq. ft. for a rate up to 36,000 bottles/hr.