Pester pac automation one of the leading end-of-line packaging system suppliers is introducing a new generation of robotic configurations at interpack this year. With its new ‘pac robot 2 3 and 4’ Pester extends the range of robot systems available for extremely dynamic packaging applications.

Pester will demonstrate pac robot 3 and 4 in a new generation of machines at interpack. Pac robot 3 will be integrated in a high-speed film wrapping machine and pac robot 4 in a top-loading robotic cell for filling trays from a thermoforming machine.

The company supplies end-of-line packaging machinery from film wrapping and case packing to palletizing to the world’s leading pharmaceutical cosmetic and food manufacturers. As a result Pester packaging equipment is installed all over the world both as individual machines and as turnkey lines. The company also offers value-added services that include engineering validation documentation training and maintenance. Headquartered in southern Germany Pester has 280 employees and some 35 agents worldwide.

pac robot – an extremely dynamic and lightweight solution

Streamlined kinematics low inertia and a specialized robotic technology package from ELAU enable the pac robot to combine highly dynamic performance with a high payload capacity. The pac robot 3 covers a wide operating range with its three axes of motion and two-dimensional freedom of movement. The pac robot 4 has a fourth axis that enables freedom of movement in 3 dimensions.

“Development of the pac robot family was vastly simplified with the help of the ‘robot library‘ from ELAU which provided all the functions we required in the form of IEC conforming software objects to run on the company’s PacDrive automation system. As a result we were able to focus on our core assignment which is product handling in the packaging process“ says Lorenz Fleschutz manager of the software engineering department at Pester. Mr. Fleschutz appreciates the engineering and validation time savings made possible by the use of ELAU’s pre-programmed pre-tested software modules. He also notes that because the robot module is independent of other machine subsystems at the software and hardware levels individual robots can be commissioned and put into operation as free-standing equipment modules instead of waiting for the entire machine to be completed.

ELAU technology packages advance the state of modularity

The robotic equipment module is one of several such ‘technology packages’ that ELAU will introduce at interpack. In the parlance of the ISA S88 (IEC 61512) standard an equipment module contains both the control hardware and software that a piece of equipment -- such as these robots -- requires to perform a task.

Similarly these technology packages integrate the company’s automation hardware software development environment and application-specific software modules with the machine builder’s mechanical systems to reduce time to market and life cycle costs. The PacDrive system’s scalable hardware range consists of controllers servo motors and drives and human-machine interfaces (HMI). The primary benefit is on the software side because machine manufacturers can readily standardize basic software structures and functionalities across their entire product portfolio. In addition to faster development standardization means fewer software platforms to support.

The robotic modules are easy to integrate as well. After the kinematics have been selected the robot is parameterized and can be synchronized for example with multiple conveyors or external master axes. Typically the robot transfers products from a moving conveyor to a different conveyor. The robot’s path is specified by simply indicating points through which it will travel.

The benefits of software modularity are far-reaching according to the new ARC Advisory Group report Software Management Strategies for Packaging Machine Builders. The study contends that innovators such as Pester who embrace modular software practices raise the value of their machinery. It singles out ELAU’s track record for promoting the standardized easy to understand software structures that packagers value while simultaneously enabling machine builders to implement competitive performance advantages.

At interpack ELAU will launch new technology packages for cartoning multipacking pick & place closing and labeling as well as the form/fill/seal functionality introduced at last fall’s FachPack show. The robot package provides a diverse range of kinematic modules that include articulated gantry delta SCARA and portal mechanical configurations.

pac robot 3 picks 300 bottles per minute

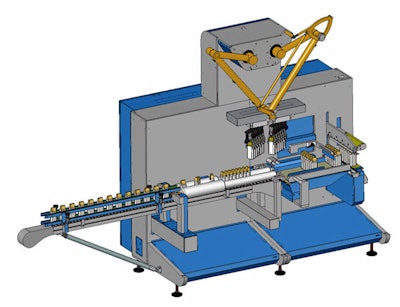

The new PEWO-pack 450 Compact film wrapping machine accommodates all standard shapes and sizes of tablet bottles for cosmetic and pharmaceutical products with film widths of up to 450 mm. The system is ideal for producing industry standard 6-packs while providing optimum product protection and the required film marking. The machine adapts readily to product changes thanks to its modular design and various infeed alternatives.

Continuous product guidance enables the PEWO-pack 450 Compact to reliably handle relatively unstable bottles at rates up to 300 pieces per minute. All the packaging operations from collating to film wrapping and shrinking are synchronized. As bottles are discharged from the labeling machine they enter the collating unit. The pac robot 3 uses two pneumatically actuated grippers to simultaneously remove two sets of 6 bottles each from the turning and collating screw. It indexes the bottles 90° and places them on the infeed belt of the PEWO-pack 450 Compact. A continuously operating inserter pushes the groups of bottles into the servo-controlled sealing unit in a single-lane configuration at a speed of 50 cpm then wraps and seals them securely in PE film. Shrink wrapping is performed in the newly developed PEWO-therm shrink tunnel which features a transparent viewing area to permit constant product monitoring.

Fast and gentle top-loading with the pac robot 4

The new pac robot 4 is the heart of a top-loading robotic cell configured specifically for packaging and handling requirements in the pharmaceutical cosmetic and food industries. This new generation of robots can also be integrated in third party machines. At the Interpack show the robot cell will be loading cartons into trays produced by a Multivac R 140 thermoforming machine. Tray packing of sterile medical devices such as syringes also benefit from the reduced human intervention of robotics.

In this demo line the pac robot 4 picks a folding carton from the infeed conveyor. An integrated vision system determines the location and orientation of the randomly spaced cartons. It communicates position and direction information to the ELAU PacDrive controller which performs the calculations for the robot to precisely orient the cartons within the trays.

The robot module also monitors acceleration at the Tool Center Point (TCP) and/or the centrifugal force applied to the product by the robot’s pneumatic gripper. The PacDrive controller automatically calculates the maximum permissible speed to avoid exceeding the gripper’s holding force. It reduces the speed of every axis as necessary to remain within the set limits. As a result stress on the mechanical system is also reduced.

“Speeds of up to 100 cycles per minute are reached with this top-loading module. Even awkward geometries or unstable products that require sensitive handling can be packaged gently at high speeds with this technology” explains Pester development manager Hans Haug.

Modular is flexible reliable and economical

To meet changing market requirements Hans Haug predicts that modularity is the future of end products as well with flexible modular machinery used to configure products and manage variants in the manufacturing process. Robots are well suited to this environment.

Fast startups a high degree of operational reliability and therefore machine availability are achieved with the ELAU software modules which have been validated on an international scale in accordance with the FDA’s GMP/GAMP and 21 CFR Part 11 requirements. Consistent use of the software modules also assures a common look and feel that reduces maintenance and recipe development time costs.

Not only does the PacDrive controller perform the robotic control – it is the only controller required on the packaging machine. The PEWO-pack 450 Compact with integrated robotic cell is automated by a single ELAU controller with a corresponding reduction in hardware and software licensing costs compared to third party robots.

Visit pester pac automation at the Interpack show Hall 15 Stand B-32 or online at www.pester.com. Visit ELAU at Interpack Hall 7a Stand E-17 or www.elau.com.