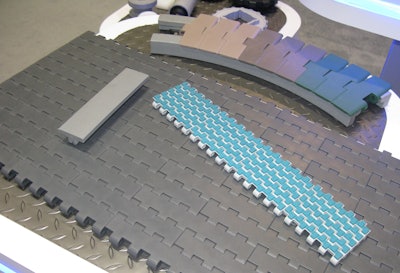

That was one of the things learned at a January 22 press conference held by Emerson Industrial Automation at Automate/ProMat 2013 in Chicago. The emphasis of the press conference was on Emerson’s System Plast group, whose plastic belts, chains, wear tracks, and guide rails helped Pepsi generate the extra revenue. What System Plast did is provide a drop-in replacement—the basic conveyor framing stayed put--to take the place of a traditional live roller conveyor. In the 110-ft stretch between Pepsi’s case packer and palletizer, all four of the System Plast components shown in the photo accompanying this story were part of the retrofit package: high-friction belts for incline and metering (light blue); top-side flexible tabletop chain (dark gray); low-friction modular belts (multi-colored); and guide rails (light gray).