"Generic drug companies have tended to be viewed as followers. We want to be recognized as a leader."

That's how David Mackay describes the thinking and planning behind Torpharm Inc., the start-up pharmaceutical company in Etobicoke, Ontario, Canada, where he manages packaging machinery installation and maintenance. "Start-up" isn't quite the right word: The firm is a division of Apotex, the largest generic drug company in Canada. But while Apotex markets primarily in Canada, Torpharm will avoid Canadian destinations. It was created with the U.S. market in mind.

"We've been inspected by the U.S. Food and Drug Administration as well as the Canadian Health Protection Branch," says Mackay.

At the time of Packaging World's visit to Torpharm, only one high-volume line was operating, and it was being used to package ulcer tablets known as ranitidine. Other packaging lines are on the drawing boards. Like the existing line, they'll be for tablets and capsules as well. What kinds of products, however, Mackay doesn't specify.

Filling into 40- to 125-cc jars of high-density polyethylene, Torpharm's turnkey line was assembled by DT Kalish, a division of DTIndustries (Springfield, MO). Though DT Kalish had turnkey responsibility for the new line, Mackay says there were two pieces of equipment that Torpharm specifically requested: an Omega Design (Exton, PA) bottle unscrambler at the beginning and a shrink bundler from Automation Packaging Inc. (Tampa, FL) at the end. Based on previous experience at parent company Apotex, says Mackay, these machines have proven their reliability. Parts availability has never been a problem either, he adds.

Other incentives behind selecting the API bundler were the machine's modest size-it's only 8' long-and no-tool changeover. "It has a smaller footprint than what most comparable systems would require," says Mackay. "Also, the shrink tunnel doesn't radiate as much heat to the surrounding area as you commonly find in similar machines." Line operators doubtless find that a blessing. As for no-tool changeover, "We request it whenever it's possible," says Mackay. "It's very helpful to have the operators make a change rather than calling in a mechanic."

Extended text a must

Torpharm management knew from the start that they wanted an extended-text label for their bottles. Such labels eliminate the need for a folding carton-and the capital cost of a cartoning machine-because important product information can be carried right on the label instead of using a separate leaflet and carton. But extended-text labels have a downside, too. They're so much thicker than typical pressure-sensitive labels, conventional rolls won't hold many. With Torpharm's line specified to run at 100 containers/min, the labeler would have to be stopped frequently to replenish the label supply. The solution? A dual-head labeler marketed byDT Kalish and made by Capmatic (Montreal, Quebec, Canada.)

"When we put the spec out we requested either two label rolls feeding one head with an automatic splicing function, or two heads that would automatically switch back and forth," says Mackay. "Our supplier elected to build a machine with two separate labeling heads that automatically take over for each other when one is empty or down for some reason."

Capmatic's LabelStar machine has been available for some time, but the Torpharm unit is the first to be built with the dual-head feature.

Its operating principle is fairly straightforward. When labeling head A runs out of labels, a signal is sent to the machine's PLC so that labeling head B will begin application. Also, the application head in A backs off slightly so that bottles can be conveyed past the peel-off plate without containers making contact with the label at the beak of the peel-off plate.

Naturally a few bottles aren't labeled during this transition, but a luminescence detector mounted near the labeler will reject any bottle not having a label. Also mounted near the discharge of the labeler is a machine vision system from Acuity Imaging (Boston, MA). This inspects labels for lot number and expiration date, which are hot-stamped onto the label by the LabelStar system. It also checks an alphanumeric label ID code that's preprinted by label converter Cameocrafts Graphic Industries (Mississauga, Ontario, Canada). If for any reason the wrong label is detected, the dispensing head is automatically shut down and the backup head started.

Unscrambling is first

At the head of the U-shaped line is the automatic unscrambler from Omega. It sends bottles in a single file to a desiccant inserter from Austin-Gordon (Nashua, NH). Torpharm was among the first to install the recently introduced machine, which employs a programmable logic controller from Keyence (Woodcliff Lake, NJ) and stepper motor from Pacific Scientific (McHenry, IL). These reduce the emphasis on gears, clutches, wiring and mechanical relays.

A photocell detects a container in position, and programming logic signals the stepper motor to advance the desiccant pouches one position. An air-activated rotary knife then cuts the pouch free from its "bandolier" and the pouch drops right into the bottle.

Desiccant pouches are from Multisorb (Buffalo, NY). For small bottles, a 1-g pouch is used, while larger bottles get a 2-g pouch. The desiccants keep the product dry and promote product stability.

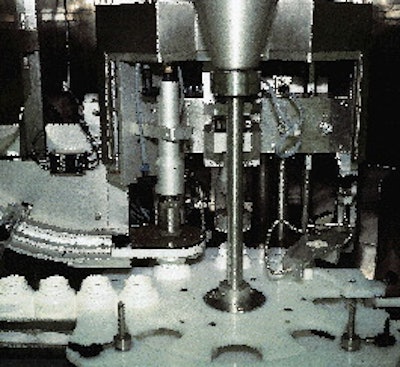

Next is filling, executed by a pair of Swiftpack electronic tablet counter/fillers from DT Swiftpack, another division of DT Industries. First the bottles are divided into front and back lanes by a diverter gate. Bottles in the back lane are conveyed beneath one counter/filler, bottles in the front lane beneath the other. The paired machines give Torpharm a packaging speed of 100 bottles/min. Photocells a short distance upstream from each counter/filler sense which lane requires more bottles and signal the gate accordingly.

Each counter/filler has a series of three 16-lane vibratory feed trays. From an overhead hopper, tablets gently tumble down from the first to the second to the third tray. By the last tray, the tablets are completely single-filed. Infrared emitters/receivers count individual tablets as they tumble off this tray. Tablets then proceed down chutes and drop freely through a funnel right into a waiting bottle. When the designated count is reached, the precount gates close, allowing the counter/filler to keep running while the filled containers are gated from the bottom of the chutes. Electronic counting continues for the tablets that are still dropping.

Exiting the fillers, bottles are combined back into a single lane and are conveyed to the capper, also supplied by DT Industries. "It's not a true rotary machine, which would have multiple capping heads on multiple platforms," observes Mackay. "But it's like a rotary machine in that it will recirculate any bottle missing a cap."

Three stations

The intermittent-motion capper carries bottles via starwheel through three stations. In the first, the bottle picks up a cap that's chute-fed from above. Second is a pre-torquing station. In the third, each closure is tested for the final application torque. "We set the torque we want," says Mackay, "and if the load cell senses that torque is too low, the bottle will be recirculated and retorqued."

Why bother with torque testing at the capper when an automatic retorquer sits a few feet downstream? Mackay explains: "Induction sealing, which occurs right after the capper and ahead of the retorquer, is done effectively only if the surface contact between the bottle and the foil liner is correct. By having the capper check application torque, we guarantee the proper surface contact."

After the inner liner is sealed on a Pillar Technologies (Hartland, WI) unit, all that remains is retorquing, labeling and shrink bundling. The API shrink bundler collates bottles in 3 x 1, 3 x 2, or 4 x 3 patterns and then pushes the bundle through a vertical film curtain. A hot knife seal bar comes down from above and a seal pad up from below to seal and simultaneously cut the film. The film is then shrunk down tightly and bundles are palletized by hand.

Sanitation measures

Also making the Torpharm line stand out are the measures taken to ensure sanitation. For instance, all electrical utilities and air supply hoses drop down from the ceiling through a single stainless-steel column. Then, through an enclosed stainless-steel trough that runs beneath the entire U-shaped line, these utilities are routed to whatever machines require them.

"It's done for sanitation purposes," says Mackay. "Other plants might have multiple connections dropped from the ceiling, but that just provides more opportunities for contamination of the area."

The same commitment to sanitation drove the development of a "service corridor" behind the walls of the packaging room. "Electrical connections, compressed air, and dust collection are all serviced outside the packaging room itself without interfering with the GMPs of the room," explains Mackay.

Also in the service corridor are temperature, humidity, and pressure sensors that are checked periodically. "We can run these checks and recalibrate or replace the sensors without having to go up in the ceiling to do it," says Mackay. "That means we don't have to clean the packaging room before going back into production. Whatever needs to be done is done from the service corridor."

The line has been running commercially now for a little over a year. Plans call for additional packaging lines as Torpharm identifies new products it wants to move into. But Mackay is clearly relieved to have one line up and running.

"We were on a tight timeline in getting this one going," he adds. "From order to delivery and startup was 12 weeks. DT Kalish bent over backwards for us."