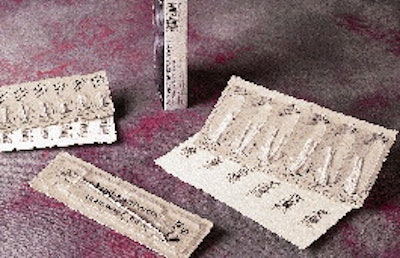

Based in Lancaster, PA, Star Dental, a division of DEN-TAL-EZ, Inc., manufactures dental tools for sale to distributors internationally. Scalers, picks and cutting instruments are among the hundreds of instruments packaged into blister cards and paperboard sleeves, then delivered to distributors. Until this spring, Star Dental applied pressure-sensitive labels containing lot and date code information, as well as labels containing bar codes, to packages by hand. Because some blister cards hold up to six individual products, that meant as many as 12 labels had to be applied to each package, creating a costly and time-consuming operation. Recent mandates from the Health Industry Business Communica<> tions Council (HIBCC), Phoenix, AZ, called for more detailed information on packages, including bar codes. This prompted Star Dental to purchase a 985 DT Coditherm Flat Product Printing System from Dalemark Industries (Lakewood, NJ). The system prints information directly onto blister cards and paperboard sleeves. It's enabled the company to meet these guidelines while cutting both labor and material costs. "We picked the thermal-transfer system because of its quick set-up," says Donald Nelms, senior industrial engineer at Star Dental. "We hadn't found anything like it in the field." The patented thermal-transfer printer produces HIBCC bar codes, "the standard used in the health industry," says Nelms. Among the identification included in the bar codes is item/catalog number, description, lot/date code, and a Labeler Identification Code. This code is assigned by HIBCC for easy identification and tracing among distributors as well as for inventory and supply chain management. After orders are received and production and packaging is scheduled, flat blister cards or paperboard sleeves are placed into the printer's feeder for coding. An integrated counter allows coding of a precise number of flats. "There are two parts to the machine," explains Nelms. "One is the infeed mechanism, a quick set-up for loading into the magazine. Second is the computer-driven printhead." An item number is called up using keypad-operated, menu-driven software, which holds programs for each of Star Dental's products. Packages are imprinted with the HIBCC code, then taken to the packaging line.