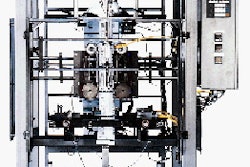

Among the more intriguing bits of technology on display at La Chien D'or's Quebec plant is the system responsible for applying the unusual one-way pressure-sensitive degassing valve (photo A) that is supplied by Plitek (Des Plaines, IL). Made by CCL Labeling Equipment (Monrovia, CA), the labeler (photo B) is essentially CCL's Stepair 230 with certain key modifications. Rated at 120 to 150 labels/min, the machine is well able to keep pace with La Chien D'or's pouching equipment. The most visible modification to the labeler is the inclusion of a nozzle that applies oil to the valve prior to application. It helps to review the structure of the valve (photo C) and its operating principle to understand why the nozzle is needed. The base layer of the valve is a 7-mil polyester with adhesive on its underside and a round hole punched in its center. Adhesively laminated on top is a much thinner polyester. The laminating adhesive is applied only to the left and right edges. Down the center, directly over the round hole, is a channel where the films are not attached in any way. Naturally there is also a release liner, with a hole that corresponds to the hole in the 7-mil base polyester. Prior to application to the coffee pouch material, each valve passes the oiling nozzle. A short-stroke piston opens the nozzle and shoots the pressurized food-grade oil onto the hole in the release liner. The oil immediately wicks out into the center channel, trapped between the 7-mil polyester base and the thin polyester top layer. Like two pieces of glass with a thin film of water between, these two layers of polyester cling to each other due to capillary attraction. The result: an airtight seal. However, when the natural release of CO2 by the freshly roasted coffee creates pressure pressure of 0.1375 psi (9.5 millibar), the airtight seal breaks and the valve opens to let the CO2 out. As soon as internal pressure drops to approximately 0.0375 (2.6 millibars), the oil causes the two layers of polyester to reseal. Though other degassing valves rely on capillary attraction, Plitek's is unusual in that no valve component comes into contact with the food product inside the package. Alain Beaulieu, director of production at La Chien D'or, also likes it from an operations standpoint. "It's applied very quickly, like a pressure-sensitive label, where conventional valves require more dwell time that slows down machine speeds," he says.