Brumunddal, Norway-based dairy stlandsmeieriet Hedmark Trrmelk has added an aseptic filling machine that's scheduled to produce nearly 10 million 1/4-L gabletop cartons of its TINE-brand coffee creamer for distribution throughout Norway this year.

Hedmark's use of the U-S80 Aseptic(TM) system from Elopak (New Hudson, MI) represents the first dairy application of the system (see PW, March '96, page 2). Installed in mid-'94, the machine first underwent six months of validation testing prior to producing cartons on a limited basis. Distribution throughout Norway commenced in mid-'95.

Production volume is determined by Norwegian Dairies, Oslo, a government-run cooperative. It's responsible for sales and marketing, new product development and exports of products produced by 14 regional dairies. These regional dairies have a combined 95 separate production facilities that accept milk from approximately 27ꯠ individual farms. Hedmark is one of the production facilities within Southeast Norway's stlandsmeieriet region.

Prior to installing the new system, Hedmark produced the 1/4-L gabletops of coffee creamer for sale only within its region. Volume was in the 2.5-million carton/yr range.

"We've produced coffee creamer in gabletop cartons since the 1970's, but on machines that were not truly aseptic," explained dairy manager Jan Bonden during PW's February visit. The interview followed a plant tour of Hedmark that concluded a two-day international media event hosted by Elopak.

"We referred to our previous machinery as 'extended shelf life' systems," he notes. "They provided a product that was shelf-stable for 60 days." With its former equipment, Bonden says, "we had to buy carton blanks from a state-run source that presterilized them via gamma irradiation." The standard gabletop filling systems included add-on HEPA air and hydrogen peroxide spray systems. The new machine was designed to be a completely aseptic system.

"The new machine has made advances in carton sterilization, ultraviolet curing, and processing techniques," notes technical manager Kjell Egil Aasen. "And this system provides a 90-day shelf life for the coffee creamer."

The 50% increase in shelf life is an impressive advantage, though the new aseptic system also:

* Triples production speed to 8걄 cartons/hr.

* Saves 800 to 1ꯠ labor hours/yr.

* Saves $75ꯠ annually by sterilizing on the machine.

The speed gain is attributable to a three-lane production process that allows Hedmark to continually produce 2꺜 cartons/hr from each of the three lines. The machine is designed to produce its largest possible size, a 1-L carton, at this speed. It could produce approximately 3ꯠ 1/4-L cartons per hour on each of the lines, though the 2꺜/hr rate suffices for Hedmark.

The machine is versatile as well, permitting simultaneous production of three different-sized cartons with the same product; Hedmark currently produces only the 1/4-L size. Three separate lanes allows Hedmark to continue production on two lanes in the event any one lane shuts down.

Besides its versatility, the aseptic system provides Hedmark with labor savings. Aasen says, "Not only did we need a full-time maintenance person with the prior system, we also required about 30 hours worth of maintenance approximately every 400 hours of production. With this machine, that level of maintenance is required every 600 production hours. In a year's time, we save about $4ꯠ."

That does not include the full-time maintenance person that's no longer required, savings that were not quantified. One that was: $75ꯠ/yr by no longer buying presterilized carton blanks.

The new system's benefits boost Hedmark's efficiency. "By producing cartons three times faster than we did before, with less downtime and labor costs, we estimate that our production efficiency is about ninety-five percent, a thirty-percent increase over our extended-shelf-life machinery," Bonden states.

Gabletops gain

In Norway, coffee creamer packed in a gabletop carton represents a considerable change. Outside of Hedmark's region, consumers previously purchased the product in an aseptic brick, produced by other Norwegian dairy facilities.

The decision by the co-op to pack coffee creamer in gabletops throughout Norway required deliberation. "Initially, the technical people within Norwegian Dairies preferred the brick packs because of some of the performance difficulties we had with our previous aseptic gabletop system," Aasen recalls. "But the marketing people preferred the easy pouring and reclosing of the gabletop. So, we set out to test consumers."

The late-'93 test involved two medium-sized towns in the southern part of the country. In one town, gabletop packs were sent to stores that previously stocked only brick packs. The opposite took place in the second town. Test gabletops were produced by Hedmark on its former equipment. Using results from Norwegian Dairies' figures, Hedmark says brick sales declined by 10% while gabletops gained 12%.

Aasen says brick packs were phased out early last year. Norwegian Dairies' sales figures comparing the July-through-December 1995 period with the same six months in '94 report the gabletop has boosted sales by 9% throughout Norway.

While this year's anticipated 1/4-L gabletop coffee creamer volume is four times what Hedmark had produced previously, the 10 million cartons will use just 40% of the machine's capacity, according to Hedmark. In the future, Hedmark hopes to boost production on the machine by introducing new products, such as flavored milks, aseptically packed into gabletops.

Limited use and future product launch uncertainties make it difficult for the dairy to accurately measure payback. Hedmark plans to pay off the aseptic system during a 12-year period. That's long by U.S. standards, but Aasen says "this is a reasonable time period in our country, since our production on the machine is dictated to us."

Three-lane filling

Production begins on the U-S80 A as an operator loads blanks into three horizontal magazines at the infeed end. Each magazine feeds cartons to a separate "lane" within the Elopak machine.

Elopak builds the Pure-Pak® carton structure at its Terneuzen, Holland, plant. The material is then shipped to two additional plants for printing, cutting, scoring and gluing. From the inside-out, the 22-pt carton includes: polyethylene sealant/a barrier layer of DuPont's (Wilmington, DE) Surlyn®/aluminum foil/PE tie layer/chemically treated pulp board/PE coating. This structure is then printed offset in four colors at the two separate converting facilities.

The unusual Surlyn/PE sealant combination provides an added measure of protection for the creamer, which includes 10% fat content. Should there be any tiny pinholes in the PE, the fat could migrate into the foil. By adding the Surlyn, which is stronger and resists stress cracking, the chance of pinholes permitting the product to migrate to the foil are extremely remote.

Sealed and sterilized

The carton erecting/sterilizing/filling/sealing system is identical on each of the three lanes within the machine. Prior to every production run, a sterilizing solution called oxonia active is used to clean all internal surfaces of the system. An automated one-hour clean-in-place procedure is done at the end of every run.

During production, suction cups open the carton, placing it into a transfer chute where a push arm delivers the carton onto one of six square mandrels on a revolving wheel. The mandrel transfers the carton to a second position where the carton bottom is subjected to sterilized hot air. The carton indexes to another position for additional heating. At the fourth position, the four bottom flaps are folded. Pressure is used to seal the heated flaps at the fifth station. At the next position, the carton is transferred off the mandrel and placed right-side-up into a pocket within the aseptic chamber.

The carton top then goes through a "prebreaking" process where mechanical devices fold in the stiff board along its score lines, then open the carton back up to permit complete sterilization. Prebreaking at this point eases downstream top sealing, making it easier for plows to push in at these score lines prior to sealing.

Subsequently, the carton's interior and exterior are sprayed with a 2% hydrogen peroxide solution. Then they're exposed to UV light to kill surface bacteria. Elopak plans to upgrade the UV light system at Hedmark in the next few months to further enhance its reliability. Hot, sterile air is then blown downward into the center of the carton. When the air hits the bottom, it moves back upward along the carton's interior sides. This process removes any potential hydrogen peroxide residue.

Afterwards, an infrared sensor checks the shape of the carton. If carton flaps were accidentally dented during prebreaking, the sensor detects the imperfection, sending a signal to block the fill for that carton, which will be discharged downstream.

On to filling

Sterilized, bottom-sealed cartons proceed to a "double-diaphragm" filling system, used on each of the three filling lanes. During filling, a piston moves up and down within a cylinder. As the piston moves downward, it pulls coffee creamer from a fill bowl down into the cylinder.

Two check valves make this process work. One valve is positioned between the piston and filler bowl, while the other is below, between the carton and piston. When one valve is open, the other is closed. When the piston pulls product down, the upper check valve opens while the bottom valve closes. When the piston stops and begins its ascent, the top valve closes, while the bottom valve opens, discharging product into the carton.

The double-diaphragm includes two circular-shaped pieces, measuring about 6" in dia, that are drawn by vacuum to the piston, within the cylinder. The primary purpose of the diaphragms is to protect the product from contacting the moving cylinder, which could cause contamination. Should a breach occur, the system would not be able to hold the vacuum of the diaphragm against the piston. A sensor would signal the fault and the machine would shut down that particular filler.

After filling, cartons pass a dosing unit that can be used to flush the carton headspace with nitrogen and carbon dioxide. This is not used for coffee creamer.

Next, the carton is top-sealed. This is done in a two-step "soft heat" process, similar to that done for the carton bottom. Flaps are folded inward and subjected to pressure and heat to create the seal. When Hedmark first began using the aseptic system, it encountered some sealing difficulties.

Elopak's director of the Juice and Aseptic Specialty Div., Johannes Osmundsen, admits, "our engineers were so concerned with obtaining a hermetic seal that we wound up oversealing cartons." Hedmark's Aasen adds, "Many consumers of coffee creamer are senior citizens, and opening the carton can be difficult, especially if they have arthritis. Our engineers worked with Elopak to make adjustments in the two-stage heating process to obtain the hermetic seal while also making sure that cartons could be easily opened."

Off-line checkweighing

Cartons discharge from each of the machine's three lines. A Fas-Co Coders (Chandler, AZ) machine hot stamps production and 90-day expiration dates, and HT (for Hedmark Trrmelk), onto the horizontal seal area along the top of each carton.

The operator checkweighs six cartons from each line approximately every 20 minutes. This check is performed on an off-line scale just downstream of the filler discharge. The average weight of the six cartons from each line is entered into the machine via a keypad. This information is relayed to a programmable logic controller that signals the filler to make adjustments when necessary.

"We considered completely automated in-line checkweighing, but we determined that it would add a great deal of cost to the process," says Aasen.

Vibration and moisture also played a role in the decision. Hedmark and Elopak determined that as cartons discharged at fast speeds from the three lanes, vibration of the cartons on the conveyors could cause weight miscalculations with an in-line checkweigher. And a few additional grams of weight from moisture pick-up either within the machine or the plant, could also cause inaccuracies.

"We were concerned that in-line checkweighing could cause the filler to react to every fluctuation in carton weight. With three lines running at the same time, this could cause a great deal of uncertainty, and slow down production," Aasen says.

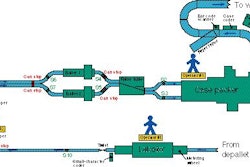

Gabletops are automatically packed 16 per case, in a 2x4 configuration, on a WAP 3000A machine from Nor-Reg (Honefoss, Norway). A corrugated divider separates the two layers of cartons within each case. The machine uses hot melt to seal the corrugated cases. A Marsh (Belleville, IL) LCP ink-jet unit codes cases with a best-before date as cases ride an incline conveyor to a Holmek (Reinsvik, Norway) palletizer. It arranges 17 cases per layer, in a cross-stacking pattern, with six layers/pallet. Pallets proceed to another area of the plant for stretch wrapping and distribution.

Pallets are trucked to three Norwegian Dairies distribution terminals. Local dairies order product from these terminals, delivering orders to retailers. The 1/4-L carton retails for 8 to 9 Norwegian Krone, around $1.30 U.S.

Like the previous cartons with a 60-day shelf life, the aseptic cartons produced on the U-S80 A are sold in refrigerated sections, though refrigeration is not necessary for the aseptic gabletop to maintain its 90-day shelf life. All testing done to confirm the longer shelf life was conducted at ambient temperatures. Selling the product in the refrigerated case is done because a cold product blends more evenly within a hot cup of coffee than if kept at room temperatures.

"We've been very pleased with the system," says Aasen. Bonden takes particular pride in the fact that the system led Norwegian Dairies to assign Hedmark with gabletop production for all of Norway. When asked to give a bottom-line evaluation of the system, Bonden's thumbs-up signal speaks volumes, in any language.