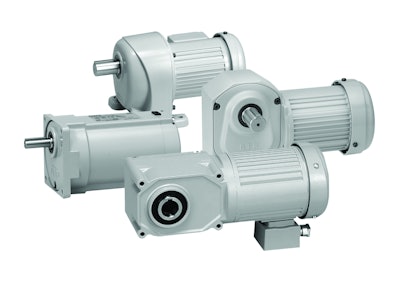

This large product variety allows Brother Gearmotors to meet customer needs with a 3- to 5-day delivery, as well as provide emergency overnight delivery when necessary. Brother Gearmotors is one of the world’s largest fine-pitch gear manufacturers and meets industry demand for smaller, lighter, reliable and energy-efficient power transmission components.

At the Bartlett facility, on-site technology also makes available a more comprehensive product mix to North American customers, including 16 different gear ratios and six voltage options. In addition, Brother Gearmotors’ expanded range of bore sizes open up a broader potential customer base for the company’s gearmotors.

Key attributes of gearmotors from Brother include:

- Light, reliable and compact in size

- High torque at low speed

- Sealed for life for maximum efficiency and reduced labor

- Standard high-grade grease for lifetime lubrication and reduced maintenance/downtime

- High-quality, durable, e-coat paint to withstand the toughest environments

- More efficient than worm gearboxes as a result of hardened hypoid gearing