Food manufacturers have utilized the retort or autoclave process for years, typically to help preserve vegetables, beans, fruit, soup, sauces, baby food, meat/fish, ready-to-eat meals, and pet food. To meet code requirements before, during, and after the retort process, Videojet Technologies, a global leader in coding, marking and printing solutions, introduces innovative V476 and V521 inks for use with its 1000 Line of Continuous Inkjet (CIJ) printers. V476 is qualified for use in Videojet standard 1000 Line printers and V521 for use in its 1000 Line Ultra High Speed models.

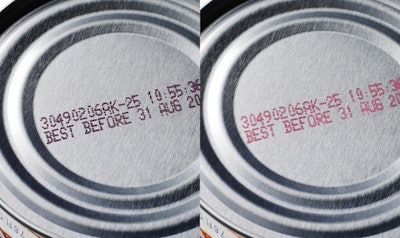

Codes produced with these new inks provide a noticeable color change from dark red to light red when exposed to heat and moisture during the retort process. The color change occurs after the material has been retorted for several minutes at 240 - 250° F (116 - 121° C). This allows processors to determine whether or not a particular item has been properly exposed to the retort process.

“These new inks are an example of Videojet innovation in fluids for inkjet technology,” says Heidi Wright, Business Unit Manager for Supplies at Videojet. “We are continually looking for ways we can deliver unique fluid formulations to meet customer needs and are very excited to bring these products to the industry. These new inks are a result of our dedicated research and development initiatives. By working closely with our customers to determine their production needs, we can collect application data that can be used in creating formulations for a specific set of production requirements.”

MEK-free and methanol-free, Videojet V476 and V521 inks provide a clear color-change from dark red to light red and offer reduced bleeding of the code as compared to other thermochromic ink offerings. Primary uses for V476 and V521 inks are for processed food containers such as metal cans, glass jars, flexible pouches, plastic bowls, and trays. These inks may also be used in food or pharmaceutical applications where the goal is to reduce certain solvent plant emissions, including MEK.

With 40-plus years of ink development experience, Videojet continues to invest significant resources to create leading coding and ink solutions for a vast range of substrates and applications. Addressing a variety of customer challenges, the company continuously monitors packaging trends, regulations and customer needs to help ensure solutions are innovative as they meet manufacturers’ printing requirements.