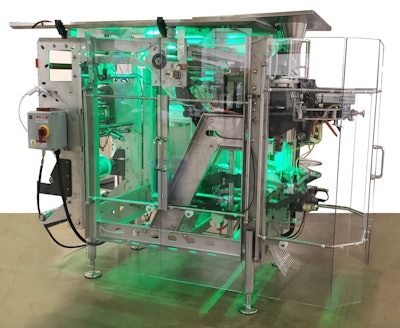

BW Flexible Systems’ new Hayssen ISB (intelligent sanitary bagger) aims to provide best-in-class sanitary design, modern industrial machine intelligence and intuitive operation for vertical form-fill-seal packaging. This new machine debuted today at PACK EXPO Connects 2020.

To develop the Hayssen ISB, BW Flexible Systems conducted voice of customer interviews in target markets—including fresh produce, frozen/individual quick freezing (IQF) and cheese—asking about pain points and preferred features.

“What we heard in those conversations was a need for an unparalleled hygienic design that was easy to change over, flexible and intuitive to operate,” said Ed Haarsgaard, BW Flexible Systems’ Sales Leader for new machinery. “The Hayssen ISB delivers a powerful sanitary design and modern intelligent systems, made possible by our customer-centered approach and deep flexible-packaging knowledge from decades of experience.”

The entire machine is high-pressure washdown capable, including its human-machine interface (HMI), which would typically require protection due to its sensitive components. This VFFS has earned an IP66 weather-proofing rating and a NEMA 4X rating for enclosures. Other hygienic features include its frame, which is an open-channel design with sloped surfaces built to have no more than one square-inch of surface-to-surface contact between components. Furthermore, the Hayssen ISB uses standoffs and flanged fasteners to eliminate secondary hardware like washers, and the bagger’s film rollers are fully removable without tools and come completely sealed with lifetime bearings. In addition, vacuum belts, a potential source for contamination and pathogen growth, have been eliminated in favor of friction belts.

The Hayssen ISB’s HMI can be equipped with cellular network capabilities to communicate with tablets for training opportunities without affecting production needs. The VFFS can self-diagnose potential issues in real-time and automatically calculate program values to maximize performance.

Changeovers on the Hayssen ISB are toolless except for the sealing jaws. The machine features passthrough film threading, and its entire unwind and film path has been engineered to provide immediate film tracking adjustments. Film tension is managed and maintained automatically using a laser measuring system.

To view the demo in its entirety (available through March 31, 2021), and add BW Integrated Systems to your MyConnects Planner, click here.