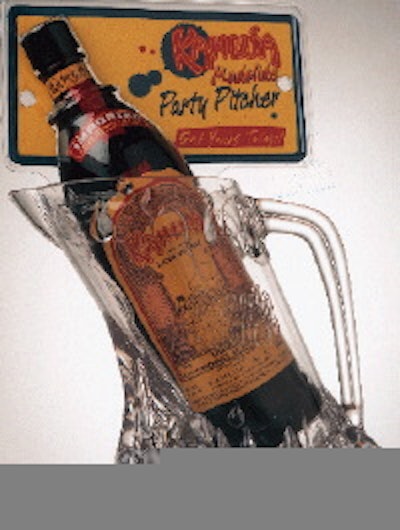

The one-piece hinged thermoform of clear polyvinyl chloride must cushion the glass bottle within its plastic pitcher during distribution, and it also must display the bottle and product attractively in supermarket liquor departments and other retail outlets. Package Development Co. (Rockaway, NJ) forms the clamshell from 15-mil PVC sheet. Its most distinctive feature is a prominent "inner tube" near the top, which lets the bottle rest snugly inside the plastic pitcher. Hiram Walker workers assemble the pitcher parts at the firm's Ft. Smith, AR, facility. In addition to the bottle itself, they add a paper insert card that functions like a header card. The 10-pt paperboard card is printed offset in four colors by Ludlow Printing (New York, NY). Once all the components are in place, the clamshell is folded and closed via two locking buttons in the header card area. Test shipments before the promotion was launched showed a likelihood of some cracking in the bottom of the pitcher, so an expanded polystyrene pad was added for cushioning purposes. Extra protection comes from a six-cell assembled partition inserted into each six-count corrugated shipper. The Hiram Walker promotion budget gets hit pretty hard by the cost of all these components. The pitcher costs $1.74 and the clamshell plus card come to 54¢. The selling price of the 750-mL bottle, meanwhile, is $14.99. But management believes the money is well spent. As Kurylo puts it, "Value-added packages that give customers something to take home are very effective promotions." This particular promotion was set to run through March and April.