This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

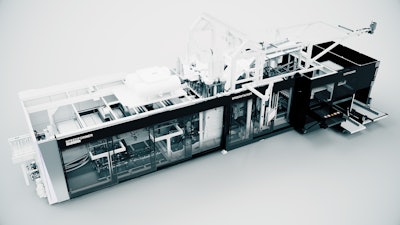

KIEFEL GmbH, an expert in the design and manufacture of polymer and natural fiber processing machines, automation and tools, has launched the new tilting machine SPEEDFORMER KTR 6.2 SPEED for the mass production of polymer cups and coffee capsules. This technology solution provides higher productivity and production versatility while offering 10% energy savings due to optimized heating.

Increased output thanks to optimized technology and design

The new SPEEDFORMER KTR 6.2 is designed for large-scale production of high-end thermoformed polymer cups, offering up to 50% higher output at the same footprint & quality compared to other machine manufacturers.

“This increased output is possible thanks to its larger forming area combined with faster forming time due to an improved tooling cooling process. Additionally, the filling time is drastically reduced owing to the optimized forming air system," says Alexander Donabauer, Director Sales of the Polymer Packaging Division at Kiefel.

Stronger punching force and taller polymer cups

The KTR 6.2 features a more powerful drive system at the Trim-in-place station, offering an impressive punching force of 900 kN. Therefore, this cutting-edge tilting machine can easily punch a wide variety of materials, including thicker films, such as PET, which usually require stronger punching forces.

Furthermore, the machine technology is enhanced to produce higher cups up to 250 mm.

Cups and coffee capsules made of various polymers produced on the KTR Series.

Cups and coffee capsules made of various polymers produced on the KTR Series.

New advanced stacking & automation solutions for faster production

Additionally, customers can achieve even higher production speed with two innovative modules: the optimized and integrated SPEEDSTACKER for efficient and higher stacking, which can handle a greater number of products and a wider range of geometries, as well as the new downstream automation CUPPACKER for cup packaging, which can be optionally integrated into the KTR 6.2. They offer product optimized transfer that uses real-time monitoring to guarantee maximum speed and output and smooth machine movements.

“Moreover, the KTR 6.2 includes a new intuitive user interface, KMI 2.0, which facilitates thermoforming processes, supporting customers from a short training period and fast recipe optimization to efficient error handling and a targeted maintenance system," adds Donabauer.