This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

igus® has increased its range of available bar stock materials to include its proprietary polymers iglide® A350 and iglide J350. Blue iglide A350 is suitable for medium to high loads and temperatures up to 356 degrees Fahrenheit. The material also conforms to FDA guidelines and can withstand acidic environments, which means it can be used in the food industry.

The highly wear-resistant polymer iglide J350 is suitable for rotational applications and is extremely low friction - especially when partnered with steel shafts. High loads, shocks and impacts are no problem for iglide J350. Its high temperature resistance up to 356 degrees Fahrenheit means this material is suitable for a wide range of applications.

With the addition of these two new materials, iglide bar stock is now available in eight different lubrication- and maintenance-free plastics.

Injection molding special parts within days instead of weeks

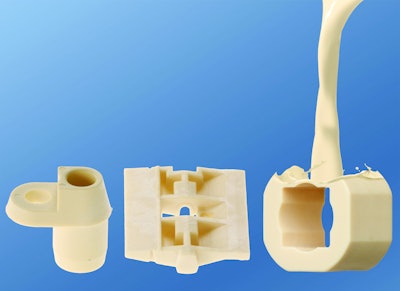

Thanks to a new method of manufacturer tools, customers can now get user defined injection molded parts in less than 24 hours. Without minimum order quantities the Speedigus process is ideal for prototypes with volumes. Standard serial tools usually need four to eight weeks to be finished and usually the cost is amortized over the production run, however with Speedigus individual parts can now be produced and shipped in one day. Customers only need to deliver a 3D CAD file (preferably STEP) and specify the desired number of pieces.

Currently Speedigus parts can be made of iglide G, J, L280, T500, M250, P, A180 and H2 as well as igumid G, the igus Energy Chain® material. Tool manufacturing and production will be done in a maximum of fifteen days from the order. Every Speedigus offer comprises of comprehensive technical information about the components including information for the lead time of tool. The costs for Speedigus systems start at about $1,500 USD and parts starting at $0.10 USD each. Part of the service is also to store customer specific tools for possible repeat orders along with tooling maintenance.