This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

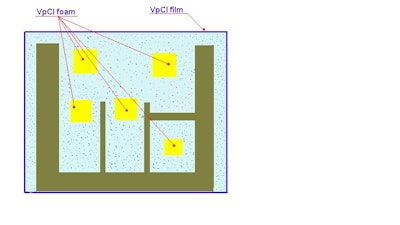

This line of products is represented by unique, flexible packaging materials that combine VpCI® corrosion protection, cushioning and desiccant action, plus excellent antistatic capabilities - all in one step, enabling customers to eliminate expensive and messy rust preventatives. All materials are safe for the environment and do not contain harmful toxic compounds like nitrites and chromates. Parts protected with Cortec® VpCI® -130 Series Foams are always ready for use, no degreasing or coating removal is required and more importantly application of these multifunctional materials results in significant weight, labor and cost savings!

These packaging materials provide continuous multimetal protection to ferrous, non-ferrous metals and alloys such as: steel, copper, brass, aluminum, zinc, solder and silver, protecting against humidity, condensation, galvanic corrosion and residual impurities. They perform excellently even under aggressive conditions found in marine environments and extended storage in non-air conditioned warehouses.

VpCI® -130 Series Foams contain 10 times more VpCI® chemical per square meter of subtrate than other wrapping materials as well as unique combination of high and low vapor pressure VpCI®, which makes it excellent for long-term protection of large surfaces like big export packages, crates and seagoing containers. The product line will not change physical or chemical properties of electronic components.

This series quickly became a global bestseller and is selected by world leading companies such as Heidelberger Corporation who was experiencing corrosion on the most sensitive unpainted components during export of their machinery. Combination of VpCI®-137 foam and VpCI®-329 oil additive, reduced the corrosion to near zero while also reducing handling costs of the company and it's customers. U.S. Air Force's problems with backup generator that was rusting severely due to an extremely salty environment were solved after VpCI®-132 foam was inserted into the generator cabinet.

VpCI-130 Series Foams conform to NACE Standard TM0-2008, and RP0487-2000, MIL-I-22100C and are RoHS compliant.