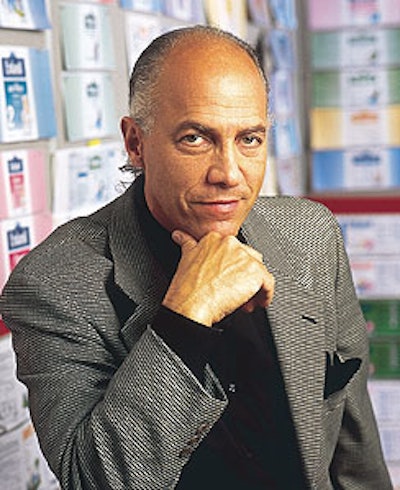

With nearly 100 years of experience in infant nutrition, Mead Johnson Nutritional Products is just finishing up a complete graphic design overhaul of its vast Enfamil family of baby nutritional products on a worldwide basis. Nearly a full year of work with The Biondo Group (New York, NY) culminated in the creation of the “Enfa” superbrand with a graphic appearance that will be recognizable anywhere in the world the products are sold.

The project involved the global redesign of packaging for worldwide standardization and upgrading and repositioning of the Enfa products’ images for high quality and heightened shelf impact.

The redesign project was spread over nearly 600 different packages around the world. Some 450 of the SKUs were outside the United States. “Strategically, the ‘Enfa’ brand could travel around the world,” says Stuart Kipperman, president of global design for Mead Johnson Nutritional Products, Evansville, IN, a division of Bristol-Myers Squibb in New York. “The Enfamil brand here becomes Enfalac in some parts of the world, and there are other brands like EnfaMomma.”

Thus, “the graphic identifier we developed evolved from the company’s existing equities,” says Charles Biondo, president of the design consultancy. “The Enfamil logo is a very strong icon, so the new design drops that name out in white on midnight blue in a rectangular field that’s outlined in satin ribbon with the proprietary Enfamil bow in the center.”

In addition to infant formulas, the new brand encompasses products like cereals, toddler foods and infant nutrition for premature infants, toddler nutrition, vitamins and supplements, and oral electrolytes. These products are produced and packaged in three MJNP plants in North America and three other MJNP plants in the Netherlands, China, and the Philippines. Some 10 other production facilities around the world are not wholly owned by MJNP.

“Before this design, each country was doing its own thing,” says Biondo. “Nowadays, with people traveling so much, companies like Mead Johnson want their packages to have a common look across borders to make it easier for consumers to find them.”

Although much of the world now has the new packaging on the shelf, Kipperman says a few countries still haven’t launched the new look. “We’re still running a business around the world, so you can’t just stop everything and start again. We launch at different times, depending on the inventory levels of current packaging, so we don’t have to discard perfectly good materials. We worked out a schedule with all the production facilities.”

Determining what’s required

The design team worked hard to separate the actual required copy from copy that may no longer be necessary. “We had to initiate a continuing dialogue with each plant and each country to actually determine how necessary all the copy and graphic details would be,” Kipperman points out. “So we had to dig pretty deeply to find out whether copy was there for preference or because it was a requirement.” This was a major responsibility of Mead Johnson’s headquarters staff.

For the most part, the project did not involve size or materials changes. However, Kipperman does note that there were some materials upgrades. “We did change our paper label spec,” he says. “We now have a specially milled paper that’s a much higher caliper than we used before. It gives us a much better presence and a more premium image on the shelf.” The company declined to be more specific about the change or identify its sources for new labels.

One of the challenges to any global package work is that there is almost no uniformity in materials availability around the world. And the same is true for the capabilities of converters in many markets.

“Alignment of materials from region to region and country to country is difficult at best,” Kipperman emphasizes. MJNP uses local sources for packaging materials, based on decisions made in concert with the local officials. The company evaluated the sources for supply to ensure they were up to standard competitively in that region.

Although the design project was totally separate from any capital investments at its plants around the world, MJNP did upgrade its packaging materials where necessary and where it had access to better quality paper or printing.

One of the biggest problems was in the varying printing capabilities for various locations. “In some cases, we were able to locate converters that could handle eight colors,” says Kipperman. “But in other cases, we were limited to six or sometimes even to four colors. Then it becomes complicated when you have an image on the packaging, rather than just typography that needs to be replicated with consistency. This is why color control was such a nightmare.”

Language a key

Easily the thorniest issue in creating all the graphics was the issue of language for the copy, and here MJNP relied on the design firm’s experience with global projects.

“This experience helps us to understand the kinds of words to be careful with, even understanding the meaning of certain colors in certain areas,” Biondo explains.

“Translating label copy is pretty easy when you go to Latin America, because you’re basically dealing with English and Spanish,” Kipperman points out. “That kind of language help is readily available. But when you get to Asia, for example, language becomes far more difficult. Fortunately, Biondo has internal resources from that region.

“What made it very accessible is that these individuals had the appropriate type fonts from those countries. There are thousands of fonts in these countries, just as we have here. To do a Chinese label, you may need a thousand fonts for all the characters. So it’s not simply a matter of a foreign office sending us a translation that we set into type; it wouldn’t work without all the fonts.”

Biondo also acknowledges the difficulty of working in several languages, but says his firm is very multilingual. His group includes people who understand Japanese, Chinese, Taiwanese, and Korean. He agrees that working with foreign language characters was “the toughest part of the whole project.”

Space an issue

MJNP and Biondo did occasionally run into space problems with the differing languages. “When you translate from English into a foreign language, even French for Canadian packages, the other language typically requires more space,” Kipperman says. “So there was a lot of communications with legal and regulatory groups to determine just what was absolutely necessary and what we could adjust to make the copy fit into the space available in our templates.”

Although the company had hoped that “shared labels” might offer them some economies of scale, Kipperman says that regulatory requirements in different countries made that almost impossible. “We may have some shared designs for front labels,” he says, “but I doubt that any of the copy on the sides or back panels could be shared among more than one country.”

Still, he says the architectural formats for the design helped the company achieve some efficiencies. “Because of the formats, we didn’t have to totally redesign the back and side labels. The copy and placement in the template meant that the information was much more concise and came together more quickly.”

Role of Internet

Both Biondo and Kipperman acknowledge that technology played a big role in securing all the approvals required for all the copy.

“Thank God for computers!” Biondo exclaimed when asked about storing all the graphic designs. “In the old days, we would have needed a second office just to store paperwork. Now, we can keep all this on a few disks. Of course, you can’t do everything on the computer, particularly proofing. And we really had to keep each country’s designs separate, sometimes using different software.”

Protected Web sites on the Internet were used to transmit images and designs around the world, adds Kipperman. Sending PDF files via the Internet is a lot faster than sending artwork by courier, Biondo adds. But some countries and facilities don’t have that capability yet. “For those countries, we had to resort to the old fashioned ‘pony express,’

now called Federal Express,” Kipperman reports. When this is combined with teleconferencing, communicating can be pretty efficient, he says.

Kipperman says the company hasn’t yet compiled any research to show any change in the business because of the new designs. But he’s heard some informal reports. One launch in Asia, he says, showed a significant sales improvement at point-of-purchase after the redesign.

However, this will be a continuing program, with Biondo managing the artwork assets on an ongoing basis. “Once you establish a megabrand, you look to make sure it stays number one in the market,” Kipperman concludes. “To that end, you’re looking at 18 months to two years for the next evolution of the brand, all based on the competitive environment.”