What better opportunity to explore new, more efficient packaging equipment than a consolidation of packaging operations? Seminis Inc., the world’s largest seller of seeds to commercial fruit and vegetable growers, is a perfect example. The firm recently closed two plants and combined its operations into a brand new facility in Oxnard, CA. Canning and pouching operations were both upgraded significantly.

The steel cans Seminis uses come in two sizes, 404x700 and 201x400. Automated equipment used previously consisted of two combination scales feeding two downstream seaming machines. Each scale/seamer pair was dedicated to one can size.

Now replacing this equipment in the Oxnard plant are two new scale/seamer pairs. Unlike the older systems, however, in which seaming took place downstream from the weighing/filling operations on a completely separate piece of equipment, the new equipment integrates filling and seaming stations in one automated transfer system. Thus, the amount of floor space required for packaging equipment in the new plant is greatly reduced.

Making this possible is a Model F1 container transport system from Optima (Goshen, NY). Operating at speeds to 45 cans/min, it positively captures each can from an infeed conveyor and then moves it around a long oval-shaped track. As cans move around this track, they stop once to receive a load of seeds and then once again beneath a BM2 can seamer, also from Optima. Placement of lids and lid seaming are both done automatically.

Weighing and delivering the seeds on each line is an eight-head Ishida combination scale from Heat and Control (Hayward, CA). Accuracy has been greatly improved since these were installed, says plant engineer Jim Silveira.

Seeds are expensive

“On the old lines we used vibratory feeders mounted over a load cell,” says Silveira. “They weren’t very accurate, which was especially bad because some of these seeds we package are incredibly expensive.”

Description of can contents is no longer done by weight but according to seed count. “We count by weight,” Silveira explains.

In other words, after weighing out 1 kg of seeds, the firm uses a machine to count them. If the number of seeds in 1 kg equals x, then to package ½ of x Seminis selects ½ kg as its target weight. For 2x, target weight is 2 kg, and so on. A slight overfill is built into each package because selling fewer seeds than the label specifies is simply not an option. But even with a deliberate overfill, the savings since the new equipment was installed is significant. “By reducing overpackaging from 1.5 percent to 0.5, the Ishida scales paid for themselves in about six months.”

An added advantage is that the combination scales are easy to clean. “When we switch from one seed to another, every single seed has to be removed from the scales before we can begin on the new seed,” Silveira says. “A thorough once-over with a high-pressure air hose does the trick.”

While the combination scale adds accuracy, the F1 transport system brings flexibility. “In the past, we had one line for large cans and one for small,” Silveira says. “If, for example, we didn’t have an order ready for the small cans, that line stayed inactive. Now, if we have multiple seed orders for the same size can, we can run one order on one line and the other on the other line.”

Helping to make the F1 transport system so flexible are quick-release clips and fasteners on the guides that transport the containers around their oval track. These snap securely into place with no need for tools. “In an hour we can go from running one size to the other,” Silveira says.

New and improved labeling

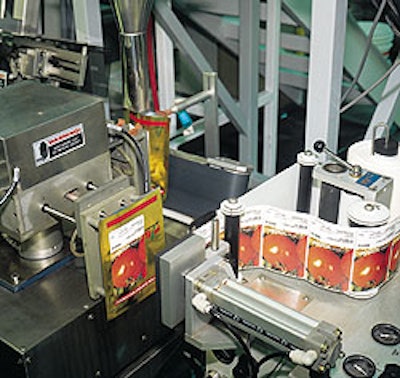

Labeling got an upgrade at Seminis, too. Both new can lines have a p-s labeler from Quadrel (Mentor, OH) that routinely applies front and back labels and occasionally adds a third label on the can top.

Not all information is carried on labels. Standard company identification, warranties, notices to purchasers, and other information is preprinted on the sidewalls of the cans. But other information varies so much that preprinting doesn’t make sense. So this information is carried on pressure-sensitive paper labels that are applied online.

For example, if hybrid cantaloupe seeds are being packed, a label with a photo of a cantaloupe is applied by the Quadrel labeler. The only copy it carries are the words “hybrid cantaloupe.” Designed into the bottom of this label is a white space for thermal-transfer printing of things such as seed count, germination time, germination percentage, lot number, source of the seeds, etc. All of this information is printed offline ahead of time on a Sato (Sunnyvale, CA) printer. Eventually, says Silveira, this printing will be done online at the Quadrel labelers.

Another can label applied by the Quadrel system is a back label with more regulatory and administrative copy, no graphics. Accurate placement of front and back labels on the round can is essential, and both labeling stations are designed accordingly. First a sensor detects can presence. Then a second sensor detects the position of the can seam, which is unprinted. Based on where the seam is, the can is spun by three rollers that surround it until it’s properly oriented. Only then does the can pick up a label, pulling it from its release liner. Exiting the labeler, cans are manually case packed.

Progress in pouching

Not all seeds at Seminis are filled into cans. Pouches are popular, too, and here again, the firm has greatly improved its method. Premade pouches are the key. They come in one small size, 135x175 mm (5.32x6.90”), and one large, 219x304 mm (8.63x12.0”).

“Most of the pouches used to be filled on vertical form/fill/seal systems,” says Silveira. “But changing over to a new brand took too long. With preformed pouches, if the brand changes, the operator just replaces the pouches in the magazine feed.” That, says Silveira, is much easier than replacing a roll of film on a f/f/s machine.

Supplied by Schwarz Packaging (Laporte, IN), the small pouches are made of a lamination of 60-ga biaxially oriented nylon/low-density polyethylene/.00035” foil/DuPont Surlyn/60-ga biax nylon/Surlyn/linear low-density PE. Seeds with pointy ends are packed in these pouches, which is why the material spec is so robust. The larger pouch, on the other hand, is a lamination of cellophane/LDPE/LLDPE. It’s supplied by Kapak (St. Louis Park, MN).

Pouch filling is now done on two Pouch Pro systems assembled and integrated by Urania (Hazleton, PA). Each U-shaped Pouch Pro system consists of the following: a magazine feed for preformed pouches; two rotating turrets that present pouches to two Quadrel pressure-sensitive tamp labelers; a Sato thermal-transfer printer mounted on the second Quadrel labeler; a scale/filler made by Actionpac (Ventura, CA); and a heat sealer.

One Pouch Pro system can do either large or small pouches. The other is dedicated to the smaller size only. Pouches in either size are run at about 20/min. The packaging sequence on either line begins with two Urania rotary turrets, each equipped with four vacuum pickup tools.

Turret A picks a pouch from the magazine feed with its vacuum pickup cups and rotates counterclockwise 90°. This positions the pouch squarely in front of a Quadrel tamp labeler. It applies the back label, which displays only copy. The turret rotates another 90° to an empty station and then 90° once more. Here the pouch is handed off to turret B, which proceeds to rotate counterclockwise 90° to position the unlabeled side of the pouch in front of the second Quadrel tamp labeler. This machine applies the front label, which carries an attractive photo of the full-grown vegetable. The preprinted front label is thermal-transfer-printed with variable information in a white box near the bottom; the Sato system mounted on the Quadrel labeler handles this printing. One final rotation of 90° positions the pouch beneath the fill spout of the Actionpac filler, which drops seeds into the pouch right after a vacuum cup device pulls the pouch open.

The Micro109XC2 linear net weigh filler feeds seeds from an overhead hopper to two weigh buckets that drop seeds into pouches alternately. The filler uses a specially modified load cell and sophisticated electronics to deliver accuracy to 1/100 g, says Actionpac’s John Dishion.

As soon as seeds are in the pouch, the vacuum cups holding it release their grip, and the pouch drops about an inch onto a transfer conveyor. The pouch leans back at a slight angle against a rail so that as it nears the infeed of the heat sealer, its top is easily grasped by the opposing rollers that propel it through the heat-seal tools.

According to Silveira, the pouch sealer has a pinch-and-pull feature that helps ensure seal integrity. “If you just push the pouch between the heat-sealing wheels,” he explains, “you might wrinkle the material, which could result in a bad seal. So as the heat-seal rollers grab the leading edge of the pouch, a pinching mechanism holds the trailing edge momentarily to pull any wrinkles out and give a good secure seal. Seals are critical, too, because moisture would ruin the seeds.”

Also setting the rotary band sealer apart, says Urania’s Joe Zorba, is that it includes a programmable logic controller. The system uses a combination of sensors and software to diagnose any moment when heat, pressure, or speed is off target.

Pleased with the progress made thus far, Silveira and colleagues are adding a few finishing touches to the packaging operations at the Oxnard plant. “Right now we feed cans by hand onto a circular feed table,” Silveira says. “We’re working on a more automated system of unscrambling and feeding. And the thermal-transfer printing of can labels that now is done off-line will soon be done online.”