The new unit’s legibility and reliability keep the heat off production and in the salsa.

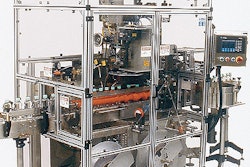

The ink-jet coder prints a one-line sell-by date and batch code on a variety of package formats from a 14-oz polypropylene bottle to 1-gal polyvinyl chloride jugs, at speeds to 60 containers/min. Print height and location varies depending on the package. Shown here is 0.7”-H coding for the 22-oz retail size PVC handled jug.

“Legibility is 300 percent better than before,” says El Toro Foods’ owner Rick Thomas, “but reliability is even more important.” Thomas says the compact printer replaces a bulky model that had been in operation about half of the company’s 21-year history. Worse than its size had been the upkeep it required.

“The print heads were constantly in need of priming: for startup, after lunch, after break, during the day, and at end of day,” Thomas explains. “When the print heads clogged, they needed to be completely taken apart, cleaned, and reassembled. This new system is a hundred times more efficient.”

Thomas says the Squid Ink unit is primed via push-button at the start of the day, and again at the end of the day. It also requires a periodic clean out, he adds, but that’s it. The previous unit, because it had clogged frequently, required two print heads whenever there was a change in ink, such as when using yellow ink on a black closure. That’s not needed with the Squid Ink coder.

“The issue wasn’t just downtime—cost savings in ink alone due to priming has been huge,” says Thomas. “The money we’ve saved just on ink will pay for the unit within a year’s time.”

Because of the different packaging formats that run five days/week, Thomas says they “definitely put the coder through its paces. We are constantly changing the print head position and keying in different coding, but the ease of doing all that also makes this system nice.”