Macco Adhesives, a division of ICI Paints in Cleveland, offers DIYers a unique series of products designed to solve 99% of all household gluing needs. Three Perfect Glue products—in a variety of formulations and containers—are all packed inside virtually identical blister packs for sale through hardware stores, home centers, and other retailers.

The primary product, Perfect Glue 1, is formulated and packaged here in the United States. It is filled into a proprietary 0.75-oz laminated tube supplied by Montebello Packaging. The tube is topped by a unique high-density polyethylene applicator cap that’s molded by Barrett Plastics. The applicator cap was designed by Liljeqvist & Wargo, a brand design firm that also created the graphics for the blister pack that’s produced by Display Pack.

The other two Perfect Glues are manufactured and packaged overseas. However, Liljeqvist & Wargo helped Macco to identify Far Eastern sources for the packaging that would replicate the blister pack of Perfect Glue 1. The key to the three products is a usage chart (left) on the back of each blister card that helps consumers match the right product with the two materials the consumer wants to glue together, what Macco calls a “Surface-to-Surface Matching system.” Each blister pack also includes a face card, a small mixing tray, and an instructions sheet.

“The Perfect Glue 1 tube is a very specific lamination from Montebello,” says Robert Tiedemann, project manager for industrial and environmental products at L&W. “The Flex Spread applicator closure, with a 0.208-inch orifice, is a custom design for which we’re seeking a patent. This product is a water-reactive glue, so it cures with water and air. The applicator cap allows the user to manipulate the glue on the surface so it’s evenly applied.”

Although the tube construction was not revealed, Tiedemann says it went through months of testing for product compatibility and shelf life. “Montebello was very thorough in this,” he adds.

The design of the applicator cap caused some consternation at the end of the project because it doesn’t permit induction sealing. That’s because there is air space around the inside of the cap that wouldn’t permit the seating of the foil liner. “The cap shape will not allow induction sealing,” says Melodie Elliott, a spokeswoman for Macco. “However, the sides of the cap make it easier for the consumer to hold the cap and use it as an applicator tool.”

In the end, Montebello elected to ultrasonically weld the foil seal onto the tube before the closure is applied, Tiedemann says. Barrett Plastics, he notes, did a terrific job in translating the L&W design to a production cap. “The resulting cap is about 99 percent of what we designed. There was very little sacrifice in converting,” Tiedemann reports.

However, the cap design also required special tooling to be made for several points in the process, one set for Montebello for cap application and another set to hold the tube for the plant that fills the product into the tubes.

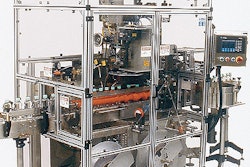

The blister pack

Once the small tubes are filled, they’re loaded into the blister packs. Blisters, formed by Display Pack, are made of 15-mil polyvinyl chloride, while the mixing tray uses 12-mil PVC. The insert card is 12-pt SBS, printed offset in five colors. The back card is printed the same to show through the front blister; the back is printed in just one color.

“If you look at the packages for Perfect Glue 2 and 3, you’ll notice they are made elsewhere,” notes Elliott. “We were able to get all three packages to match, despite coming from multiple global vendors. Not only do the blisters match, but also the inserts, instructions, card stock—even the shipping cases. We think this is a notable achievement.”

Perfect Glue 2 is filled into a 0.35-oz low-density polyethylene plastic bottle with a clog-free storage cap. Perfect Glue 3 is an epoxy product that comes in two metal tubes. Its mixing tray has a mixing scale molded into it.

“Our goal was to capture category innovation,” says Lance Liljeqvist of L&W. “This was achieved in the new product development phase and was fully leveraged with an integrated brand packaging, retail merchandising, and communications program. [This line] has all the essential brand-equity elements for success.”