This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

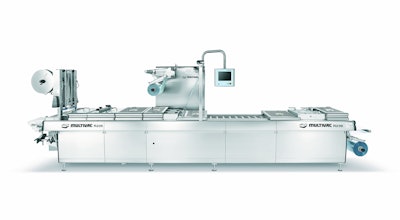

The new thermoforming packaging machine is equipped as standard with format sets and sealing dies, which are specially tailored to producing flat packs of sliced products. The R 235 can be equipped with additional preheating in the area of the forming station to ensure that the maximum cycle output is achieved.

"The sliced products market in Central Europe is growing very strongly and the competition is great. With the new R 235 we are offering this sector an efficient and economical solution," explains Dominik Eberhard, Product Manager for thermoforming packaging machines at MULTIVAC.

Efficiency all along the line

The R 235 has an interface for linking a slicer. Thanks to a lowered film infeed, the loading conveyor of the slicer can be placed horizontally at the height of the machine frame. This enables the length of the machine to be reduced significantly. The R 235 is very flexible as regards the use of packaging materials, cutting units and formats. The standard widths are based on the typical formats for packs of sliced products. A quick- change system for the forming and sealing dies makes it easy to convert the machine to other pack formats. Various labelling and marking sys-tems can also be integrated easily. The R 235 can also be equipped with a jumbo film unwind for lower webs to reduce machine downtime.

Simple operation, reliable hygiene

Thanks to the HMI 2.0 user interface, even inexperienced operators are able to operate all the functions of the machine at the touch of a finger. As with all MULTIVAC machines, the R 235 is designed in the Hygienic Design, which enables the machine to be cleaned easily from the in- side and outside. The machine can be extended in a modular way and is suitable for the integration in automated packaging lines.