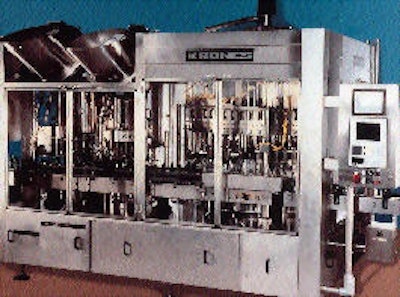

Designed for carbonated, noncarbonated and hot-fill products. A dedicated electronic valve computer controls filling valves, whose functions are performed with external, pneumatic valves instead of actuating cams or levers for a low-maintenance operation. The filling valves allow product to flow without the use of an airlock, sump or springs. Part change permits easy switch to and from glass or plastic. Allows simple change-overs as the valve seat is the only moving part. May be used in a monoblock setup with a rinser, corker, crowner or capper. Control screen permits easy setting of product feed and fill rates, heights and speeds. Additionally, fill height adjustments may be made with the computer without interrupting production.