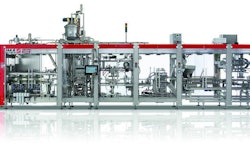

At its PACK EXPO Las Vegas booth, Ohlson Packaging, a Duravant company, exhibited its new Inline Cup and Tray System. The machine is designed for liquid, powder, scale, volumetric, hand, and specialty filling, accommodating up to six lanes of cups or trays ranging from 2 to 12 in. wide, at speeds to 20 cycles/min/lane.

The cup and tray system also allows for modified atmosphere packaging as well as automatic lid placing, shrink banding, date coding, labeling, automatic case packing, and a case-shrink system.

It also integrates seamlessly with Ohlson Packaging’s existing products, such as multi-head and linear scales, conveyors, and other packaging automation equipment.

“We are continually proud of what our team is able to develop to meet the packaging demands of our customers,” said John Ohlson Jr., President and CEO of Ohlson Packaging. “This new system will allow us to help even more companies improve their operations.”

Among the features of the machine are the following:

- Traveling indexing assembly

- Top-sealing station with optional gas flush

- Quick tool change for different containers

- Variable speed infeed/discharge conveyor

- No container – no fill sensor

- Safety switches and E-stop

- Stainless steel framework and food-grade materials

- Fully adjustable guide rails

- Anti-vibration leveling feet

- Easy-to-use color touchscreen operator interface

- PLC controls

Watch a video of the system here.