Shapes and sizes include rectangular, square, round, oval, octagonal--virtually any shapes available in the food packaging industry. Tray compositions include aluminum, foam, foil, metal, surgical plastic trays, plastic tubs, paperboard, etc. Each stack is separated by side pneumatics systems and dispenses 1-6 trays at a time.

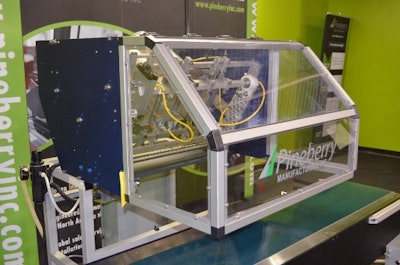

Tray denesting pick and place systems use speed matching technology to accurately and positively dispense trays onto an existing conveyor belt. Automating the tray denesting process reduces downtime generated by missing or unseparated trays, and avoids the low speed and high cost of manual denesting. High efficiency combined with simplicity and low maintenance offers quick turnaround times, durability and reliability to load various stack sizes and shapes.