This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The new belt features a patent-pending universal design that allows both left and right turns, and S-curves.

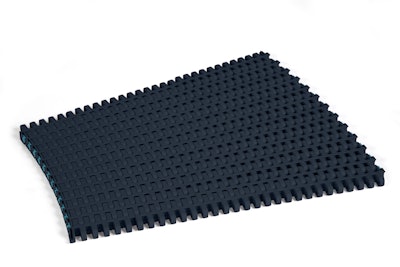

Produced in the U.S., Series 2257 belt is injection molded with the new proprietary NG Evo thermoplastic or long wearing XPG low-friction acetal. It is available in a one inch (25.4 mm) pitch, in standard widths of nine to 24 inches, with four different clip styles to meet the retention requirements of the application. Rated for a maximum working load of 450 lb (2,000 N), it is ideal for unit handling applications where it can maintain product orientation through turns. Series 2257 belt handles a minimum radius as small as 17.13 inches, excellent for compact system layouts or spiral conveyors. Thermoplastic construction makes the belt highly resistant to thermal changes, corrosive chemicals and abrasion. A low coefficient of friction and low moisture absorption allow conveyance of heavy loads with minimal horsepower.

Available in unique NG Evo thermoplastic

NG Evo is a proprietary thermoplastic designed for high-speed running with exceptionally low noise and energy requirements. Based on original NG resin, the new NG Evo has a lower coefficient of friction, higher breaking load, greater elasticity and higher wear resistance. The companion Nolu®-S wear strips and guides reduce friction even further. They are made of a unique resin with a solid lubricant that dramatically reduces the coefficient of friction. The combination of NG Evo chain and Nolu-S wear strips can reduce a conveyor’s energy requirements by up to 30 percent, with service life as much as five times greater.

Ideal for unit material handling in manufacturing, distribution centers, assembly operations, etc.

Plant engineers can determine their own potential conveyor cost savings using a new mobile app that calculates cost reductions from various choices of motors, drives and flat-top conveyor chains, as well as quick changeover guide rails. The FREE mobile app can be obtained from the mobile app page at www.emerson-ept.com.