If anyone questions the ability of thermal inkjet to work in tough hostile industrial environments then they need to see what the coders at Dal-Tile Corp. are doing. The thermal inkjet printers are putting a precise code on irregular surfaces at speeds of 220 pieces per minute. And all the time they are being assaulted by what is essentially cement dust.

Dal-Tile manufactures distributes and markets high-quality ceramic tile products. The largest U.S. ceramic tile manufacturer and one of the largest in the world Dal-Tile currently operates 10 manufacturing facilities in the U.S. and Mexico and employs over 7 persons. Company operations have greatly expanded and now incorporate the manufacture of glazed and unglazed floor tile glazed and unglazed ceramic mosaics and unglazed quarry tile.

If putting codes on ceramic tiles sounds like an easy task consider these conditions. First the printing has to go on the edge of each tile—that’s a configuration that is 5/16-inch high. The surface is rough. And each tile’s shape means that the code has to fit into a precise location that is just about an inch long.

The coding technique that ultimately answered this challenge is an Evolution brand thermal inkjet printer from Digital Design Inc. Cedar Grove NJ. The units use HP thermal inkjet technology—the same technology that works in office printers. The technology’s hallmark is simple installation and simple operation in tough environments.

Scott McNulty maintenance lead at Dal-Tile’s Dallas plant says he was skeptical that this technology had a place in his plant. “Honestly I didn’t think these printers would work” he admits. “But they have performed reliably they don’t require maintenance and are easy to run in our operation.”

McNulty’s skepticism has roots in his experience with earlier continuous inkjet technology particularly downtime for maintenance and shutdown for production lines to fix coders.

The exact nature of the coding challenge is revealed when looking at operations in the Dal-Tile plant. There ceramic tiles are carried flat on a conveyor at speeds of 200 feet per minute. That translates to 220 tiles per minute.

The first plus the HP print heads brought to the operation was their small size which allowed installation at a number of locations along the line. “All it required was two bolts to attach the bracket to the line” McNulty explains. “I have 110-volt electricity nearby and I just plugged the units in. I had the whole thing up and running in 15 minutes.”

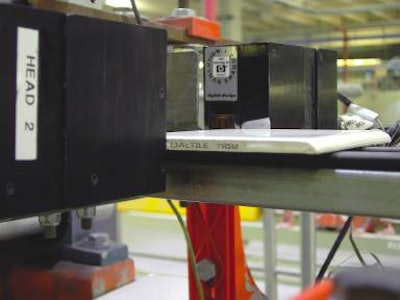

The unit is comprised of a Digital Design controller and thermal inkjet print heads. The task can be accomplished with only one print head and does not require stacking of units. Codemark Systems Dallas was the distributor that delivered the units to Dal-Tile.

One controller two print heads

Dal-Tile runs two printheads off one controller by linking them with an RS485 connection. Each print head is on an opposite side of the conveyor putting a code on opposite edges of each tile. After the first set of print heads the conveyor rotates the tiles 90 degrees. Then about 10 feet down the conveyor a third print head with its own controller puts the same information on a third edge.

The installation is simple because Dal-Tile does not need to change over codes even though the equipment has that capability. Rather the printheads just imprint the term “daltile trim” on each tile as it zips by on the conveyor.

Tolerances are tight. The imprint characters themselves are just 1/8-inch high centered on the 5/16-inch width of each tile. Imprints must also be centered on each tile’s length. The surface on each edge is interrupted by two “lugs” cast onto the tile; the lugs are spacers when tiles are installed. Registration of the imprint along the length of each tile is also a tight tolerance that the equipment has to maintain.

And another requirement in the operation that further stretches the thermal inkjet equipment’s capabilities is the print distance. Normally printheads are positioned with a 1/8-inch gap between the printhead and the surface being printed. However Dal-Tile needed to move the heads to 1/4-inch from the surface because of irregular piece heights and some “bounce” as tiles move along the conveyor. “The imprints remain sharp even though we’ve opened up the gap” McNulty says.

The company is using an HP print head with 42 milliliter ink capacity and a specially formulated ink. Each cartridge lasts about a month according to McNulty. A readout from the controller gives maintenance personnel a status report on remaining ink signaling when to change cartridges.

The closed ink supply is a plus says McNulty who explains how the plant environment has created problems with older continuous inkjet printers used in other operations. “Our plant generates dust and when it mixes with ink we get clogs” he explains. That translates into time-consuming clean ups on the conventional continuous ink jet heads. And those systems often leak adding to clean up efforts.

But the thermal inkjet system eliminates contamination of the ink supply and eliminates leaks. “If we have to clean a print head because of dust we simply wipe the thermal inkjet print head and it works perfectly.”

Please click here to read the sidebar to this story.