Nature’s Way Purewater, which bottles its own brand of water as well as private label brands, invested in a $4 million production expansion to fill 1- and 2.5-gal jugs of water (see sidebar). The Pittston, PA-based company also took the added step of networking the operation, partly to help protect its lightweight high-density polyethylene jugs from damage. Crompton Sales (Methuen, MA) was the production line and network integrator.

One of the special features of the network is what Crompton’s Scott Mueller calls “an end-run modem”: an external modem located at the end of the cable on the Allen-Bradley Data Highway Plus® network from Rockwell Automation (Milwaukee, WI). Since the modem is on the network, it allows any vendor to access the programmable logic controller of its own machine. That makes this setup unique—modems have been inside packaging machines for years, but rarely are they on a network. This allows the modem to be used as a universal remote troubleshooting aid.

For security reasons, the modem is located in a locked room to which only the plant manager has access. Additionally, the modem is connected to a phone line only when it is needed. Only then will the plant manager provide the vendor’s technician with the password to gain access to the network.

The system was used three times—all by different vendors—near the startup to assist in troubleshooting, all “very successfully,” reports Mueller. He estimates this saved at least $10ꯠ in potential travel and related expenses for service technicians.

Network strategies

Their lightweight containers mandated strict control of line conditions, explains Fred Gubitose, former president and chief executive officer and now director of corporate development.

“If there’s a problem, our lightweight containers back up, which first prompts a slowdown,” he says. “That leads to a stoppage after a preset period of time before there’s any damage to the containers.”

The main strategy is to keep the 30-valve filler running. That’s achieved through a combination of conveyor buffering—there’s 1군’ of accumulating conveyor from the automated robotic infeed loading stations to the filler—and networking, specifically the variable frequency drives (VFDs) that communicate with the network through a programmable logic controller (PLC).

Nature’s Way standardized on Allen-Bradley PLCs, touchscreens, drives, and sensors from Rockwell Automation. All nine of the processors on the line are Allen-Bradley 50/4 PLCs, linked via the A-B Data Highway Plus network.

The line uses seven human machine interfaces (HMIs), including a central control A-B 50/4 PLC with PanelView 1200 touchscreen HMI that’s mounted to an 8x12’ cabinet. The cabinet, which also houses the PLCs and electrical connections, is located near the case packer.

The network also includes 25 Allen-Bradley Model 160 variable frequency drives to control the speed of conveyors. They are run by a PLC that’s linked directly to the network. The programming and drives ensure that “the filler will continue to slow down until it stops, if needed,” says Gubitose. The A-B 160 drives are used throughout the line to balance container flow, including between the servo laner and the wraparound case packer’s product metering section. Via the network, the central PLC speeds up or slows down conveyors as conditions dictate.

For changeovers, the operator can select all line settings from the main touchscreen HMI.

“For a changeover, all they need to do is touch the proper settings on the screen,” explains Mueller. Besides a selection of 1- or 2.5-gal, the operator selects the case configuration, such as 6-count, or 3-count, to be run. These selections make adjustments to all machine and conveyor speeds.

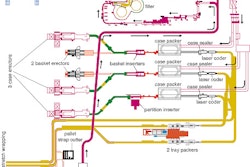

See sidebar to this article: Line overview