At Philadelphia-based PCI Services, a new system for inserting desiccant canisters has greatly streamlined production, saving time and increasing quality.

PCI, whose customers include the likes of GlaxoSmithKline and warner-Lambert, receives specific requirements from its customers, many of whom specify the use of desiccant canisters from Süd-Chemie Performance Packaging (Belen, NM). Rather than inserting the canisters manually, PCI installed three Model CDFI automatic desiccant feeders from Omega Design (Exton, PA) last year. Bob Kane, mechanical manager for PCI’s packaging contract division, prefers the desiccant canister over the desiccant sachets so commonly used in a variety of industries.

“Canisters are cleaner machinery wise,” Kane says. “Removing the step of cutting packets streamlines the production process and avoids any mess or downtime from miscut packets. The new feeders insert desiccant canisters seamlessly and automatically. Production time is shorter, and quality is higher.”

PCI uses the desiccant canisters primarily on its bottle-filling lines. Two varieties, 2-in-1 and Sorb-It, are used. The 2-in-1 desiccant canister is used primarily to absorb moisture, gas, and odor within packaging products, while the Sorb-it desiccants have an extremely high capacity for moisture at temperatures below 75? and at humidity levels above 40%. Both increase shelf life by protecting pills from moisture damage.

“We try to stay at the technological forefront by constantly searching out new and different packaging technologies,” Kane says. Sometimes, he adds, it’s customers who point the way, and the use of desiccant canisters is a good example. “Several of our customers have specified Süd-Chemie desiccants,” he says.

Moisture and odor/gas absorbent desiccants attract the excess moisture that is present within the package. Typically, a small amount of moisture will settle in the package, even under very low humidity. moisture is absorbed into the desiccant’s sponge-like pores, and as humidity increases, the larger pores will fill and absorb the remaining moisture. In the 2-in-1 desiccant from Süd-Chemie, gas and odor molecules are chemically attracted to the carbon within the canister.

Another benefit of the desiccant canister is its size and shape. According to Kane, the canisters are perfect for PCI’s high-speed production needs. Additionally, the canisters, unlike desiccant packets, won’t break open and leak their contents into the machine.

“The cylindrical shape makes canisters good for high-speed insertion,” he says. “Because the desiccant material is contained inside the canister, machines are never jammed by leaks. The canisters’ good quality is shown through interaction with [the desiccant feeder] systems.”

Canister quality is continuously monitored by Süd-Chemie inspectors. At a Süd-Chemie facility, up to 1ꯠ printed canisters can be produced per minute. A sophisticated system also enables canisters to meet tight weight specifications. Several times a minute, random samples of canisters are automatically weighed, data points are collected, and fill weights are adjusted.

In addition to Süd-Chemie’s efforts, PCI also implements its own quality-control measures focused on rigorous internal standards, Kane says.

High-speed insertion

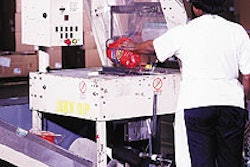

All Omega desiccant canister insertion units have safety covers that protect from dusting, decreasing the amount of down-time necessary to clean the units. The machines also have user-friendly programmable servos that aid in set-up procedures.

Each system occupies 3’x5’ of floor space and can easily be moved to different production rooms. Bottles are conveyed to the first of two air-activated devices that control the movement of the bottles. The first device holds an individual bottle under the insertion device, and when the canister is inserted, the device retracts and the bottle continues down the conveyor. The second air-activated device holds upstream bottles back to reduce line pressure.

The three CDFI desiccant feeders have increased canister insertion rates from 120 bottles/min to 160 bottles/min. According to Kane, the three units are performing so well for PCI that the company is considering the purchase of additional Omega units to keep up with demand. (ALR)