In the injection-molding business, StackTeck serves as a global provider of integrated plastic tooling. That can include anything from product and mold design to complete systems integration. The company aims to deliver high productivity for caps, closures, thinwall packaging, technical and medical markets.

Its medical mold experience focuses on medical disposables, research, testing and diagnostic plastic components and medical packaging. “In many cases, these components are very intricate, requiring complex mold ejection sequences and/or designs, as well as quality optical finishes,” says the company’s website.

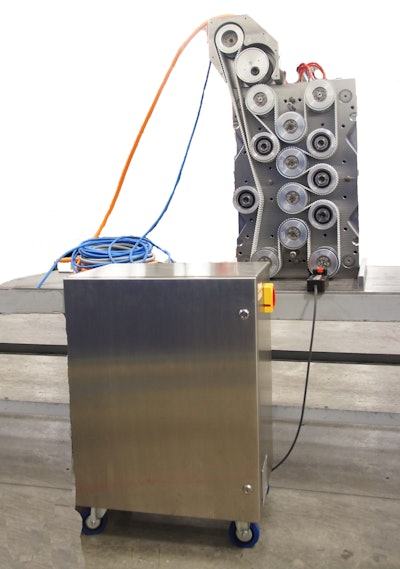

In December 2016, StackTeck noted that it had “successfully developed and implemented servo drives for two high-cavitation molds for cleanroom applications. This technology enables a more effective arrangement of mold drive shafts, belts and pulleys while incorporating a sealed drive system.”

StackTeck manufactures the molds, while the servo drives, pulleys, and belts are purchased from a global supplier.

The company explains that unscrewing molds are typically used to injection-mold closures and fitments that have a heavy-duty internal thread (as opposed to strippable threads that are typically used on beverage caps).The unscrewing action is used to unwind the part from the mold and eject it without causing deformation to the thread.

Servo benefits

The servo drives (and molds) provide the following benefits:

• The servo drive approach is more suitable for cleanroom molding than conventional unscrewing molds that use a hydraulic cylinder that drives a large rack assembly on top of the mold. Converters prefer not to have either hydraulic components or racks that need grease to run in a cleanroom environment.

• The mold runs faster, due to quicker and more precise rotation to eject the parts. Productivity of the injection molding system is improved.

• Better energy efficiency and reduced maintenance work as compared to conventional molding process.

• In many cases, the tall conventional molds are problematic for mold installation and changeovers. The servo molds are much easier to handle with standard crane lifting heights.

In general, for all types of injection molds, StackTeck builds most of its molds for converters. In some cases it supplies them directly to brand owners.

Due to their proprietary nature, some details specific to servo-driven unscrewing molds were omitted.

StackTeck has developed and implemented servo drives for two high-cavitation unscrewing molds for cleanroom application. This technology enables a more effective arrangement of mold drive shafts, belts and pulleys while incorporating a sealed drive system.

Servo-driven technology features include the following:

• Drive system is encapsulated and well-suited to cleanroom molding

• Parts are available directly

• Improved energy efficiency when compared to a hydraulic rack-and-pinion system

• Mold maintenance requirements are lessened

• Simple system with single pendant and five buttons to control—unscrewing speed is accurate, faster and is controllable

• Compared to hydraulic unscrewing molds, servo offers superior part ejection control and reduced cycle time

“Servo-driven molds bring benefits to customers looking for efficient unscrewing mold designs that are more compact and suitable for cleanroom molding. Every customer I talk to is interested in the servo approach and considering that’s available at a very modest premium, we expect it will become the new standard for the industry,” says Vince Travaglini, StackTeck’s VP of Sales and Marketing.

“In one case, a single-cavity prototype ran with conventional hydraulic technology with an unscrewing time of 1.0 seconds. However, when we ran the 16-cavity production mold the unscrewing time was reduced to 0.3 seconds—that’s more than three times faster,” notes Jordan Robertson, the company’s GM of Business Development and Marketing.