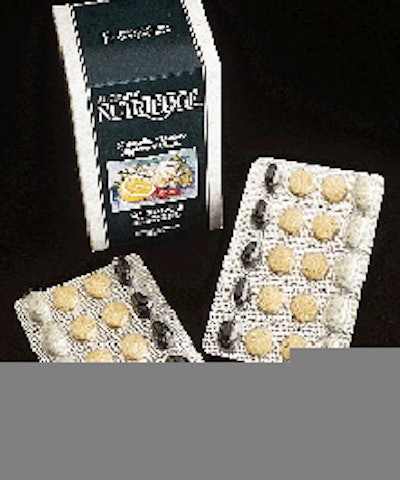

Putting several dissimilar vitamin tablets on a single blister card can be a real challenge. That's what Amway's Nutrilite Div. discovered as it moved its NUTRIEDGE(TM) antioxidant dietary supplement packaging in-house instead of contracting it out.

The blister cards contain one beta carotene gel capsule, two round vitamin C hard-pressed tablets, and an oval vitamin E hard-pressed tablet. Nutrilite encountered three problems. First, the round vitamin C tablets tended to shingle during feeding. Second, the soft gel beta carotene capsule can be sticky, hampering feeding. And third, the vitamin E capsule has an oval shape that makes it difficult to consistently place on its back in the blister cavity.

After looking at blister packers from several manufacturers, Nutrilite chose Campak USA (Livingston, NJ) to engineer a completely integrated packaging line from thermoforming through cartoning. All of the components on the machine are from Campak, except for a foil imprinter from Adolph Gottscho (Union, NJ). The line has been operating successfully since its January '97 installation.

The Campak machine is interesting because it incorporates one universal or brush-style feeder and two dedicated or channel-type feeders, all on the same machine. The feeding section was extended an additional 31" to accommodate this unusual combination of feeders.

"It was a complicated project that took a lot of engineering," says Bryan Auxier, who oversees the 25ꯠ sq' packaging operation at Nutrilite's 23-acre campus in Buena Park, CA. "We spent close to a year just working out the details," he adds.

Packaging for four countries

The vitamins are packed 20 to a card, consisting of five perforated strips of four tablets each (one beta carotene, two vitamin C and one vitamin E). Each strip constitutes a daily dose, and is separated by the consumer at point of use. Six five-dose cards are packed in each carton, a month's supply. The product is sold in the U.S., Canada, U.K. and Germany. On the day of Packaging World's visit, product for the U.S. market was being packaged.

The line operates at 135 blister cards/min. It starts out as 11-mil Pentapharm® ACLAR® sheet from Klockner Pentaplast (Gordonsville, VA) unwinds from a roll and enters the thermoforming section. (ACLAR is a registered trademark of AlliedSignal Inc.) Blisters are formed three-up on the 9.1"-wide sheet.

The film passes under the first feeder, which is a brush box or universal feeder that feeds the soft gel capsules. A brush box was chosen because gel capsules "tend to be sticky and hard to line up with a dedicated feed," says Auxier. "We get a better fill with a brush box." A series of rotating brushes inside the box, which is filled with capsules, spin at an orientation that's slightly skewed from the centerline, helping to brush the capsules into the open blister cavities below.

The next feeder is a dedicated channel-type feeder that feeds two round hard compressed Vitamin C tablets into each blister. A channel feeder, like its name implies, relies on a channel that's cut to match a specific tablet's shape. Tablets feed from a small reservoir and descend through the channel into the blister cavity. "We had to change the profile of the vitamin C tablet because it had too much curvature," says Auxier. "We made it a flatter tablet so it wouldn't shingle in the feeder."

Immediately after the second feeder is a mechanical hair-trigger switch sensor that checks for tablets that might protrude from the blister cavities. The sensor consists of a bar that extends the width of the web, riding just above the open thermoformed cavities. A protruding tablet will knock against the bar, triggering a switch and shutting down the machine so that an operator can make a correction. (The sensor was placed after the second feeder to give gel capsules that tend to cause this problem some extra time to settle into their cavities.)

The third feeder is also a dedicated channel feeder for the oval vitamin E capsule. This tablet also proved tricky since it was hard to control whether the tablet landed on its side or back. Indeed, when the packaging for this product was contracted out, the contract packager resorted to enlarging the blister cavity so that it would accommodate the tablet no matter which way it landed. But that meant the position of the vitamin E capsules varied in each package.

Campak engineered a solution in which the channel feeders deliver the tablet into the cavity on its side. Next, small rotating brushes mounted onto the feeder immediately flip over the tablets on their backs. "Now the card looks the same every time," says Auxier.

Machine vision inspection

After the feeding section, a machine vision system consisting of an overhead-mounted black-and-white camera inspects every cavity. Blister packs with missing or partial tablets are rejected from the line after foil sealing and die-cutting. Rejects are not pushed off with an arm. Rather, a section of the conveyor flips downward for a moment so that rejected cards are conveyed off the line into a waste container instead of transitioning to the next conveyor section. Auxier says the inspection system provides virtually perfect accuracy. "We've done QC audits on finished product and never found a bad one going out," says Auxier.

After inspection, a 1.2-mil heat-seal-coated foil from Lawson Mardon (Shelbyville, KY) unwinds from rollstock and is printed with product identification information, lot and expiration date by an Adolph Gottscho imprinter. The foil lidstock is heat-sealed to the thermoformed web, which is then perforated and die-cut. Trim is rejected into a corrugated waste container on the floor rather than rewound onto a roll. The benefit: "We don't have to shut down the machine to take out a trim roll," says Auxier. "We just swap boxes."

Blisters, die-cut into three lanes of individual packs, then go through a combiner where they are narrowed to single-file. Blisters then drop off the end of the conveyor into vertical wire rails that accumulate blisters in a large stack. Groups of six blisters drop into the cartoner flights directly below. The wire rails also twist the blisters 90° to properly orient them for end-load cartoning.

Built-in accumulation

One interesting feature of the machine is the ability to continue thermoforming in the event the cartoner goes down. That's accomplished by a mechanism that diverts die-cut blisters from the line onto a table where they can accumulate for several minutes. Once cartoning resumes, accumulated blisters can be hand-stacked in a separate feeding section that counts out six blisters into conveyor flights. The cartoner can be sped up until it absorbs the excess accumulation.

Once stacks of six blisters are loaded in conveyor flights, a height probe drops down until it physically touches the foil of the top blister. If the correct height is detected, it means all six blister cards are present. Next, a literature feeder dispenses a tri-fold literature insert onto the top of the stack.

Now the blister packs are ready to be cartoned. A pusher clamp pushes the stack of blisters into the open folding cartons, which the machine erects just prior to product insertion. The pusher clamp is unique in that it pushes the stack not only from the end, it also clamps down from above and below, compressing the stack slightly for a better fit. Cartons are tucked closed and discharged to the overwrapper. Four individually film-wrapped cartons are then shrink wrapped together, and six four-packs are manually loaded into a corrugated shipper.

Labor savings

According to Auxier, the entire line from thermoforming to case packing requires only five operators. That compares to nine at the contract packager, which translates into lower operating costs. "It was a substantial savings with a short payback on the machine," he says. The company declined to reveal specific ROI figures.

Although Auxier says the machine can be changed over without tools, it does take about three hours for a full changeover. Currently, the only product requiring such a changeover is the pack sold to markets in Germany, which gets a slightly different combination of the same tablets. "It just takes that long to change out plates on the thermoforming section," says Auxier. However, the rest of the products for the U.S., Canada and U.K. require only a change to the foil printing and cartonstock.

In evaluating blister packaging vendors, Auxier says Campak was the only vendor that didn't try to change Nutrilite's package style. "Some of the other people wanted to change our format," says Auxier. "And that's kind of hard to do when you already have a product in the marketplace.

"Campak was able to come in and say 'Okay, we'll take your format and get our machine to do it.' Even though it was a complicated project, they were very flexible and worked with us."