At Mary Kay's Dallas, TX, Manufacturing Division facility, packaging line changes are much more than cosmetic. In fact, machinery additions and modifications are a part of every day life at the plant that produces more than 200 products on 42 different lines.

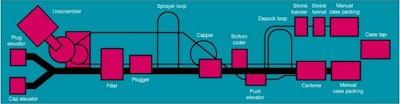

A perfect example is a dedicated line the skin care and cosmetics firm uses to pack many of its Body Care products (see Packaging World, Jan. '96, p. 2). Joining the line (see diagram, p. 74) last December was a Model 4D-RP2-12 plastic bottle unscrambler from Omega Design (Exton, PA).

By adding the unscrambler, the company no longer needed two people per shift to manually set up bottles at the infeed of the line. As a result, Mary Kay moved six workers into other positions within the plant, saving at least $120ꯠ/yr in labor costs attributable to the line. The line runs four different bottle types (see sidebar, p. 76) that vary in shape, height and neck finish, all of which necessitate machine adjustments.

Before adding the unscrambler, Mary Kay installed an RPF-8 rotary piston filler from MRM/Elgin (Menomonie, WI). The eight-valve filler was added about two years ago. It replaced two filling machines, one that handled thin liquids, another for more viscous products. Both of those machines have since been modified and added to other lines at the plant. The new filler is capable of filling 120 bottles/min, far faster than the 75 bpm speed attainable with the previous two fillers.

The line also has a shrink banding machine that applies full body wraps to individual bottles or simply applies a tamper-evident shrink band around the bottle neck. This combination was the result of machine modifications made by a rather sizable machine shop located within the 300ꯠ square-foot plant. Not only does Mary Kay modify packaging machinery to meet its line requirements, it designs and builds equipment that improves container handling along the various lines.

The machine additions and modifications to the Body Care packaging line are just the beginning. Present downstream functions such as shrink banding, manual depucking and case packing limit line speeds to 55 to 75 bpm. However, "We would like to have the entire line running at 120 bottles per minute within the next two years," states Stan Martin, production engineer at the plant, which is located about 10 miles from corporate headquarters.

Fast changeovers

Bottles are shipped to Mary Kay in bulk corrugated containers, often in quantities of 500. An operator empties the bottles into a floor-level hopper on the unscrambler. A cleated belt elevator carries bottles about 10-feet high into a circular disc sorter. Within the sorter is a sorting disc. As bottles enter the sorter, positioned on a slight angle, they fall into a channel between the sorter and disc. Mary Kay uses five different disc sizes to accommodate the six bottle sizes. Changing discs is as simple as pulling out one disc and then dropping in another. No tools are required for this changeover.

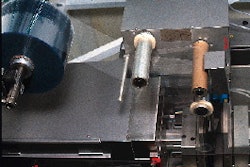

Bottles descend single-file from the sorter into a drop chute. The bottles may be neck leading or base leading at this point. Mary Kay uses five separate chutes for the different bottle sizes. Again, quick-disconnect fasteners allow rapid removal and replacement of drop chutes, without tools.

Bottles descend through the chute to a rotary pocket section of the unscrambler. Here, 12 pockets upright the bottle and send it downstream to filling. At the end of each pocket are two stainless-steel fingers. As a bottle reaches the bottom of the chute, fingers from one of the 12 rotary pockets gently grasp the body of the bottle. The fingers place each bottle into a customized injection-molded polypropylene puck from Advantage Puck Group (Mishawaka, IN). These pucks carry bottles throughout the line until bottles are ready for shrink wrapping or cartoning.

A programmable logic controller coordinates activities within the rotary pocket section of the unscrambler. Using sensors, the PLC is programmed to determine if the bottle is standing on its neck or base. If it's on its base, the bottle continues downstream. However, if the bottle is neck-down, the sensor signals the PLC. In turn, it signals the pocket to mechanically rotate the bottle 180° to upright it. Four sets of change parts are used by Mary Kay for rotary pocket changeovers. These require nothing more complex than an Allen wrench.

For Gary Tobolka, team leader in packaging maintenance, the unscrambler's ease of use makes it especially valuable for this line. "We can take an operator or line mechanic who's never seen an unscrambler, show him or her how to run it one time, and from then on that person is a master of it. The machine is very easy to learn to operate," he says.

One filler for two

Bottles discharge from the unscrambler to the filler in their individual pucks in single file.

Like the unscrambler, the MRM/Elgin filler is rated at 120/min speeds. "Before we added this filler we used two filling machines," recalls Tobolka. "We used one for thin-viscosity products, another for thicker lotions and gels. We've modified those and moved them onto other lines within our plant where they can still be productive."

In operation, bottles enter an infeed starwheel that transfers one bottle at a time onto a cam-driven platform that elevates into position to accept each bottle. Bottles are filled to volume on the eight-head rotary piston filler.

"Like the unscrambler, changeovers on the filler are easy to do," says Martin. "We adjust filler height, change nozzles and the neck guides that center the bottle under the nozzle. We're happy with the filler not only because of its changeover ease, but also because it handles both thick and thin liquids, and it reaches the speeds we're shooting for. This is something the previous two fillers for this line couldn't do. We're also happy with the filler's accuracy and dependability."

Downstream flexibility

After filling, bottles convey past an older "plugging" machine that inserts a plastic plug into the neck of certain Mary Kay products. Depending on the product, the bottle conveys to a section of conveyor referred to as a manual sprayer "loop." At this loop, operators insert a dispensing sprayer component into the neck of the filled bottle of hair spray or lotion.

Caps are automatically torqued onto bottles via an eight-head machine. Most caps are injection-molded of polypropylene, from various suppliers. Disc-type dispensing tops and high-gloss polished tops are also used, depending on the product. Again, multiple vendors supply the package components.

Capped bottles pass by an ink-jet coder that applies a four-digit black production code to the bottom of the bottle. Shelf life for these products is three years. After coding, operators remove bottles from their carrying pucks. The pucks then convey on a depuck conveyor loop that ascends over the line, returning to the puck infeed of the unscrambler.

The same material handler that loads bottles onto the front end of the line also replenishes caps and plugs. "We use a separate elevator hopper for plugs and caps at the beginning of the line," explains Martin. "We do this remotely from plugging and capping equipment because it's easier for a material handler to load plugs, caps and bottles at one area of the line rather than at separate points where the machines are located."

Modified banding

At this point, some bottles index to automated cartoning followed by manual case packing. Others continue to a modified shrink banding machine that applies a film sleeve from base to neck around the bottle, or simply a tamper-evident shrink band. The marketing staff makes the call on which bottles receive what type of secondary packaging.

For the Finishing Spray, operators manually insert a spray pump dispenser into the neck of the filled bottle. The bottle enters the bander via an infeed starwheel. The intermittent-motion machine indexes the bottle into a position to accept a 2-mil tamper-evident neck band of PVC supplied by Seal-It (Hicksville, NY).

Seal-It supplies rollstock, seaming the material so that it's in a tube form when it's sent to Mary Kay. The tube of film descends around a plastic mandrel down to the bottle. As the next bottle indexes into the machine, an air-operated reciprocating knife perforates a small area at the top and bottom of the film to make it easy for the consumer to pull off the band. A knife then shears the PVC from the tube, with the material dropping onto the neck of the capped bottle. The machine then indexes the bottle into the next position where an overhead tamping device pushes the PVC tube onto the bottle shoulder.

The banded bottle conveys through a series of heat guns that warm the material. The bottle continues through a shrink tunnel where the material shrinks to the contours of the cap and neck area, forming a tamper-evident seal. The bottle exits the tunnel where ambient air allows the film to set. Operators then manually case-pack the product to complete the packaging process.

Like any other line at the plant, Mary Kay continues to look for ways to increase its efficiency on the Body Care packaging line. "We're looking for faster shrink banding machinery, and to automate depucking and case packing procedures as our volumes justify it," Martin summarizes. "We'd like to increase the line's speed to 120 bottles a minute without losing any of the flexibility that makes this line so special to our operation."