Remedent opted for a coextruded polypropylene blister film manufactured by Tekni-Plex’s Tekni-Films Div. (www.tekni-films.com). It incorporates a core layer of cyclic olefin copolymer (COC) from Topas (www.topas.com).

The PP interior and exterior surface layers of the blister film structure provide needed inertness to peroxide, while the COC core layer delivers additional chemical resistance, high moisture barrier for a 14- to 18-month shelf life, and inherent stiffness that gives the blisters a solid, upscale feel. The blister packs are sealed with Tekni-Films’ Teknilid® WPSPPE peelable lidding foil containing a peroxide-resistant adhesive.

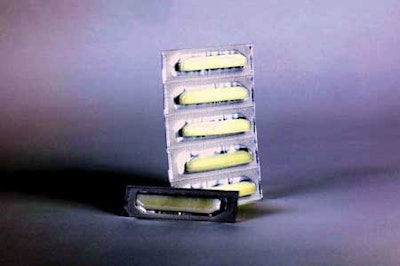

Remedent includes the blister packs of peroxide strips in two different tooth whitening products—MetaTray for dentist office use and iWhite, sold over-the-counter to consumers. With both products, the user removes a foam strip from the peel-open blister pack and positions it in a dental mold designed to hold the strip against the teeth. When the dental mold is pressed around the teeth, peroxide gel in the sponge foam strip is released onto the enamel surfaces of the teeth, and the enamel bleaching process is initiated.

Tekni-Plex developed the entire packaging system in a fast-track project to meet Remedent’s market launch date. Pol Lombaert, Remedent’s production and R&D manager for chemistry, says, “Tekni-Plex came through with an excellent package in record time.”

—Judy Rice