This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Another significant offering to Bosch’s robust portfolio, the SVI 2600 is ideal for small and mid-sized manufacturers looking to automate their packaging, as well as larger producers seeking equipment for smaller volumes or to test market new products. Bosch has incorporated the same proven technology employed on higher-end baggers, such as servo-driven cross-sealing units, vacuum belts and Bosch/Beckhoff controls, which assure reliable high-efficiency packaging.

Easy integration, advanced technology

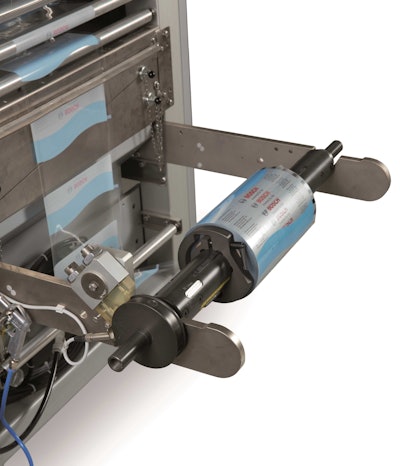

The SVI 2600 is designed to easily integrate with the customers’ existing equipment. The servo-driven sealing jaws and vacuum belts facilitate high seal precision with accurate sealing time, ensure package integrity regardless of film thickness and deliver fast operations with minimum machine wear. This is especially advantageous for manufacturers working with a wide range of films.

Simplified design for ease of use

Through simplified design and tool-less adjustments, the Bosch SVI 2600 provides user-friendly operation. The intermittent motion bagger can produce pillow, gusseted, and block-bottom bags at rates up to 100 bags per minute. The machine features open-frame construction for optimal accessibility during maintenance and cleaning, while providing maximum uptime. A large film reel diameter of 650 millimetres (25.6 inches) reduces the number of film changes required, further increasing uptime. Insulated handles on the cross seal bar help protect the operator and accelerate changeovers. In addition, large human machine interface (HMI) with intuitive icon-based navigation enables ease of use and minimal operator training.