This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

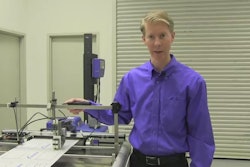

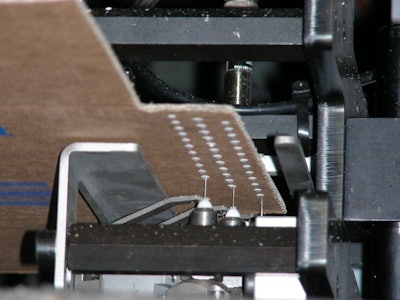

The new ERO-OE high-pressure gluing system is available in North America exclusively through HAECO and brings extra high-speed production, low maintenance and up to 40 percent lower glue usage to casemaker/flexo-folder machines. Widely used by OEM equipment makers in Europe and Asia, the affordable, easy-to-operate ERO-OE glue system has a maximum production speed of more than 2,000 fpm, and uses ceramic nozzles to prevent the formation of dried glue, eliminating daily washing. Unique in the industry, the system can apply glue in a dot pattern, as well as stripes, reducing glue consumption up to 40 percent.

The Italian-engineered ERO-OE is powered by a unique double-piston glue pump specially designed to maintain constant pressure on the glue lines and eliminate variations in the glue density, due to pressure pulsation inherent with single-piston pumps. The system's electronic 240-watt, four-channel control panel drives three independent GTE-13/S type glue valves, as well as a UV marker or, as an option, a glue detector and marker. The three-valve system delivers three individually controlled glue stripes, allowing precise pattern alignment on the ends of angled flaps. The control supports up to four photo eyes, and runs up to eight pre-programmed glue patterns, with memory for 80 additional programs. In automatic mode, operators simply set the flap angle and glue gap the first time; all other measurements are set automatically. Semi-automatic or manual modes can also be set using eight function keys.

The ERO glue detection system utilizes a 640X480-pixel resolution black-and-white camera capable of capturing 60 frames per second. It mounts on the gluing station and is monitored via the control’s 12-inch touchscreen. A data analyzer, encoder frequency divisor and LED stroboscopic illuminator are all housed in a compact electrical cabinet. The glue detection system is "mastered" by running a well-glued box through. An auto-learning system then records the image and compares all other boxes with the good sample. Boxes with glue volume or position outside the tolerance threshold are marked with ink or UV liquid. The maximum error is ±0.0625" at 1600+ fpm, and the smallest readable dot is 0.06" diameter at 650 fpm.