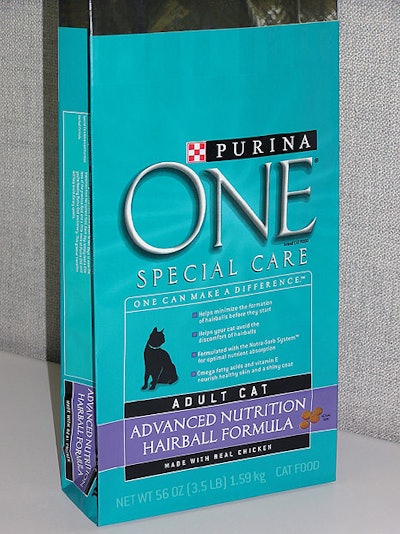

The longitudinally seamed bags are flattened and shipped to eight Nestlé Purina packaging plants where they are opened with vacuum cups, filled, then sealed and delivered to retail outlets across the U.S.

For quality control purposes, Huhtamaki recently instituted a coding system to boost traceability of these pet food bags. Using S.C.I.F.I.™ 3400 Drop-On-Demand™ ink-jet small-character printing equipment from Matthews Intl., the system prints source-mark codes pinpointing date, time, and machine number on the middle kraft layer of each bag, visible on the bag interior.

The coding helps Huhtamaki track the bags and quickly address and correct any quality complaints that might arise from any of the Nestlé Purina packaging plants that use the bags.

Steve Castellan is the facilities engineering manager for Huhtamaki’s Malvern, PA, plant that produces the pet food bags. He notes, “Although Huhtamaki’s goal is not to ship any defective product to our customers, in the event sub-standard material does reach the customer, we are confident in our ability to expeditiously trace the product history using this date-coding system and rectify the situation before further problems can occur.”

—Judy Rice