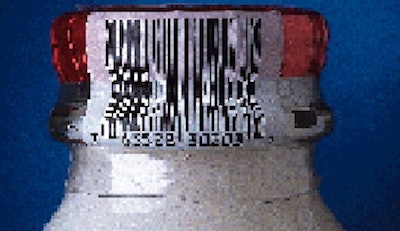

Flavors are distinguished by color and copy on the paper/foil caps, but the caps don't have enough room for a UPC bar code. So the dairy tried to bar code its bottles by means of p-s labels. Unfortunately, the labels didn't adhere reliably to the wet bottles emerging from the bottle washer. So in October '96, the dairy dropped the labels in favor of clear polyvinyl chloride neck bands with high-contrast black-and-white bar codes, supplied by Templock (Santa Barbara, CA). Since the bar code is uniformly distorted as it goes through the Axon (Garner, NC) shrink bander, it doesn't pose any scanning problems at the supermarket checkout counter, according to Alan J. Farrell, director of manufacturing. The neckband allowed the dairy to keep universal bottles while satisfying retailers, who want a scannable bar code and tamper-evidence. As Packaging World went to press, the dairy was rolling out new sizes, including pint, half-liter and half-pint, also with the bar code neckbands.