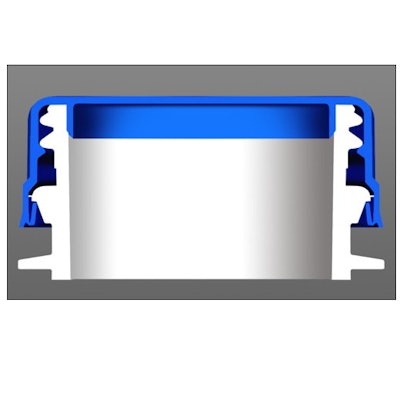

The plug design mates with the bottle finish inner surface to create an effective seal. The lightweight closure does not fail (stress crack, back-off, etc.) during the sterilization and/or distribution process. The structure withstands an aseptic sterilization environment of up to 140 degrees Fahrenheit. The closure is easy for consumers to open because there is no liner to negatively impact torque. Can be made in a variety of sizes ranging from 38 to 43mm, with or without a tamper-evident band. The cap is suitable for a variety of aseptically-filled beverages including: juices, isotonics, dairy, energy drinks, milk, vitamin waters, drinkable yogurt, teas and others.

Companies in this product