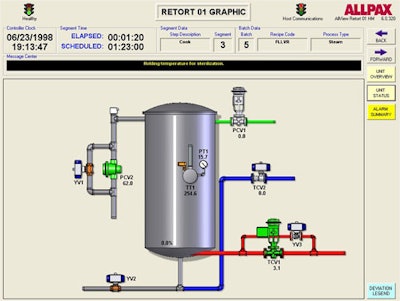

A second new software offering being demonstrated ensures higher quality and productivity in retort rooms. Maintainer software automatically tracks and alerts personnel when critical retort components are scheduled for maintenance. Maintainer also provides retort room personnel with quick access to machine documentation, maintenance tech notes, and 3D views of retort components. With maintenance schedules, concise written information, and detailed graphics at their finger tips, maintenance employees gain insight into the complex inner workings of today’s high tech retorts—insight into maximum throughput, consistent quality, and low downtime. Challenger software ensures quality and productivity by monitoring critical operating parameters and reporting on any point of deviation from norms during the retort process. At the end of a “challenge” mode, Challenger provides a written report comparing actual performance to expected performance. Challenger gives operations personnel a new and important diagnostic tool to help keep the retort process within quality and productivity norms. In addition to the two new software offerings, Allpax and Rockwell Automation will jointly demonstrate the Allen-Bradley InSite suite of remote monitoring capabilities including surveillance, diagnostics, administration, knowledge, optimization, and visualization.

All the software demonstrated at the booth will be in simulated operation with an Allpax 2402R4-Stretch research and development retort. The 2402R4-Stretch laboratory retort can process products being researched through rotary agitation and shaker agitation; and through steam, steam air, water immersion, water spray, hydrostat simulation, or sterilmatic simulation sterilization. Allpax laboratory retorts are compact, moveable, and can be rented, leased, or purchased. “Everything that Allpax does in the retort industry helps to ensure consistent quality and produce tastier food at the lowest labor cost and highest speed,” says Greg Jacob, vice president and general manager, Allpax. “Our software is in such demand that plant management asks us to retrofit competitors’ retorts with Allpax solutions. Maintainer, Challenger, InSite, the 2402R4-Stretch laboratory retort, and other offerings are a must see at Pack Expo for every packer of low-acid, shelf-stable food.”