The new press is just one part of a $10 million dollar expansion, which added 59,000 sq-ft and state-of-the-art machinery, also including solvent-free laminating and slitting to the existing facility. With the expansion complete, Kendall now has two plants with identical platforms—one in Pittsburg and the second in Jefferson, WI, giving the company the benefit of being its own back-up.

“It’s important that Kendall Packaging continues to evolve and remain on the vanguard of the flexible packaging industry for the benefit of our customers and brand owners,” said Kendall President, Eric G. Erickson III. He added, “Our most recent investment in the MIRAFLEX press technology insures that we will continue to have a positive impact on brand value through consistency, repeatability and overall package integrity. By partnering with W&H, we are able to further address our broader corporate sustainability goals, including general waste reduction, lower energy consumption and better overall environmental stewardship.”

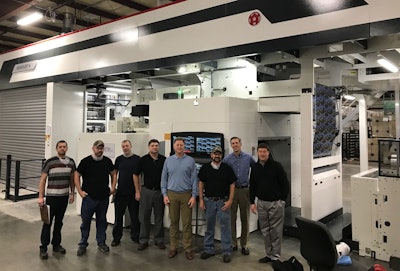

The MIRAFLEX II AM in the Pittsburg plant is Kendall’s fourth W&H press and the first such model sold in North America. It is equipped with W&H’s fully-integrated VISION web inspection system with Defect Check and Color Check, which Erickson is looking forward to having as a part of the company’s diagnostic capabilities. An additional feature on the new press is the award-winning TURBOCLEAN ADVANCED E inking and wash-up system with electric pulsation-free pumps, which significantly reduce both ink and energy consumption.